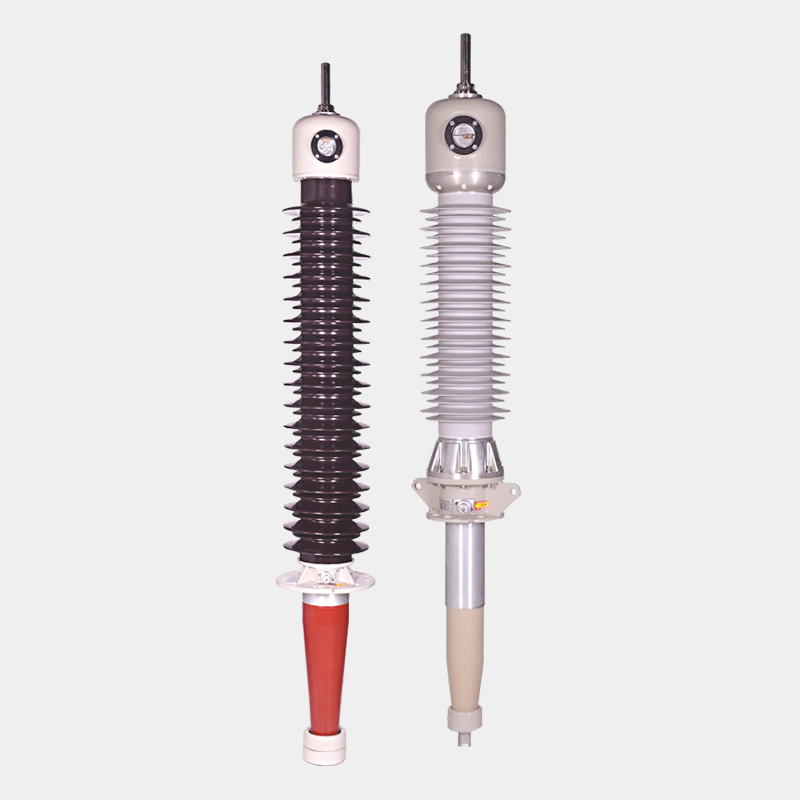

We are proud to announce the execution and supply of a prestigious export consignment of 170kV, 145kV and 72.5kV "OIP Capacitive bushings with Polymer/Silicone insulators" to a prestigious Transformer customer in "Italy" for end use with the prestigious "Italian Railways". YASH’s Sales and Engineering teams were extensively with the transformer customer during detailed engineering stage to arrive at an interchangeable solution to meet the customer’s stringent specifications including high altitude applications and could offer a design at par globally reputed European bushings suppliers.

The order was executed in a record time of 3 months despite being non-standard and special in nature and despite the challenges posed by COVID pandemic and the related delays.

Transformer bushings - "Made in India - Made for the World"

Knowledge sharing about critical accessories of Power transformers, such as Bushings thorough webinar organised by IEEMA (Indian Electrical & Electronics Manufacturer Association)

YASH could recently export a consignment of 123 kV 800A 0 BCT OIP bushing with special arrangement for retrofitting with the customer's specification as a replacement to existing bushings at site. The bushings are enroute now on a 15000 mile journey: to Final destination on the West coast of Latin America, for a renowned Power Transmission utility.

We at YASH specialise in offering custom engineered bushings solutions to meet the non-standard requirements of the end users be it in terms of the special termination arrangements, special mounting arrangements, non standard BCT space and oil end length requirements etc thereby providing a ONE STOP SOLUTION for TRANSFORMER BUSHINGS.

Quality has been one of the key focus areas of YASH make 145 kV OIP Condenser Bushings. Time and again our products are put to the test in most critical conditions, whether it is in the test field or in extreme service conditions.

Our products have proven themselves several times in the most stringent of tests whether tested stand alone or with the transformer.

One such recent achievement was successful performance of YASH make 145 kV OIP bushings during short circuit testing of 160 MVA transformer of a reputed Indian Transformer OEM.

Heavy Industries such as Steel, Cement, others which rely on continuous bulk production round the clock have a critical need of continuous power supply. A transformer bushing being a critical component in the power supply chain can cause major disruption and heavy production losses during breakdowns.

A renowned Steel Industry having a major captive power plant in the eastern part of India experienced one such emergency breakdown of the existing LV high current bushings on their Generator step up transformers and approached YASH to offer an urgent retrofit solution to the existing imported make bushing.

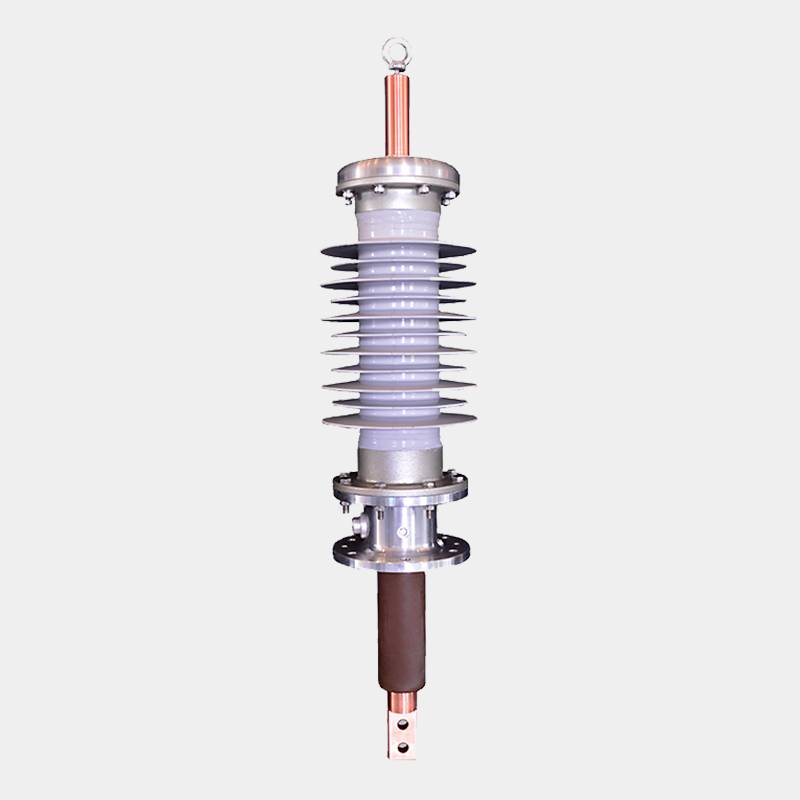

Within record times YASH could design, develop, manufacture and supply a ditto interchangeable Copper condenser bushing of 36 kV 16000 Ampere which is now operational at the Steel plant.

A transformer bushing acts as a critical exit and entry pathway to conduct power safely from/to High voltage Power lines in an out of a Power Transformer, while providing sealing to prevent contact of Transformer Oil with Air.

Bushing failures constitute the third largest cause of transformer failures globally and this is one of the key reasons why it takes a significant effort and the combination of a wide array of resources to establish as a trusted solution provider for these critical components.

With 20,000+ products successfully executed, YASH has now emerged as a niche and trusted player among a list of very few globally reputed transformer bushings manufacturing MNCs.

We thank all our patrons, suppliers, team members and stake holders for supporting us in achieving this milestone and look forward to creating many more like this in the coming years.

.jpg)

.png)