Rated Voltage : 24 kV- 170 kV for IEC range OR 25kV – 161kV for IEEE range

Rated Current : 400 A – 3150 A*

Insulation : Oil-impregnated paper– Hermetically sealed

Application : Transformer – Outdoor

Type : Oil to Air

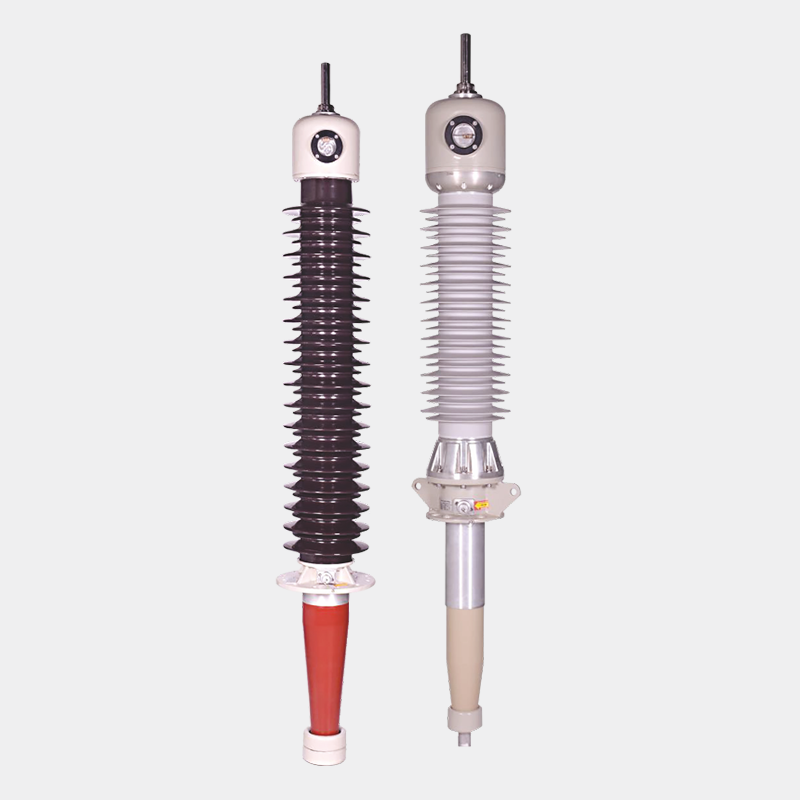

Insulator : Porcelain / Hollow Composite - Silicone

Standard : IEC 60137: 2017/ IEEE C57.19.00/01

Connection : Draw lead/Draw Rod/Solid Conductor

*Customized Rated Current >3150A are available upon request

The most widely used bushings in the high voltage transmission industry globally even today, Oil Impregnated Paper (OIP) Condenser Bushings are manufactured using Kraft paper wound tightly on a conductor, with a finely graded capacitive arrangement using intermediate layers of aluminium foils, dried under heat and vacuum to remove moisture and carefully impregnated with processed transformer oil.

At Yash, we engineer various product lines of OIP Condenser bushings with different voltage and current ratings and combinations of insulator options including porcelain or silicone.

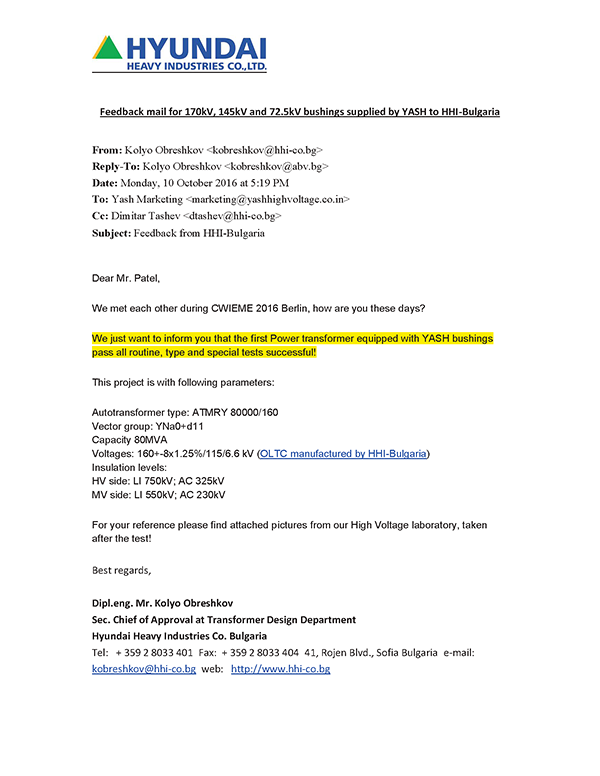

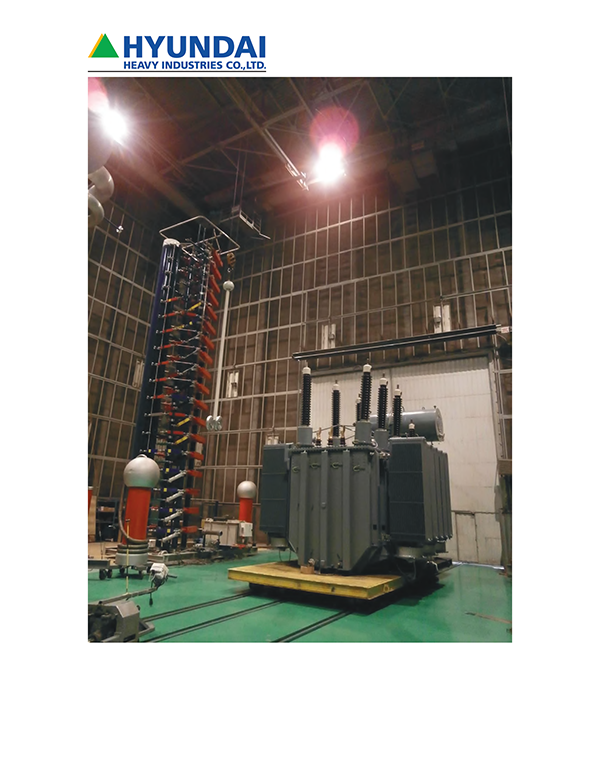

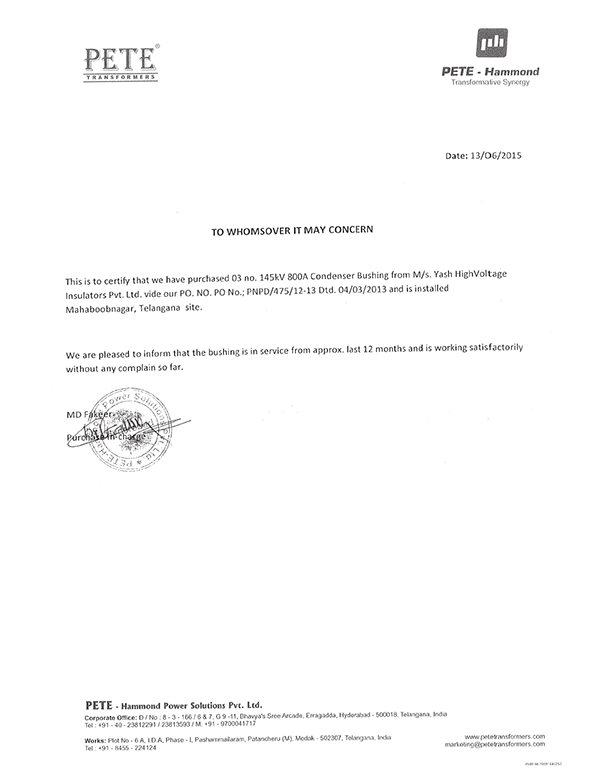

All our standard models are type tested at ILAC/NABL Accredited laboratories as per IEC-60137/IEEE C57.19.00/01. For any fresh type test requests, we request you to approach us on individual basis and we can work out a techno-commercial solution suitable for you.

- Rated Voltage: 24 kV- 170 kV for IEC range OR 25kV – 161kV for IEEE range

- Rated Current: 400 A – 3150 A*

- Insulation: Oil-impregnated paper– Hermetically sealed

- Application: Transformer – Outdoor

- Type: Oil to Air

- Insulator: Porcelain/ Hollow Composite - Silicone

- Standard: IEC 60137: 2017/ IEEE C57.19.00/01

- Connection: Draw lead/Draw Rod/Solid Conductor

*Customized Rated Current >3150A are available upon request

**Detailed drawings of our bushing variants are available upon request.

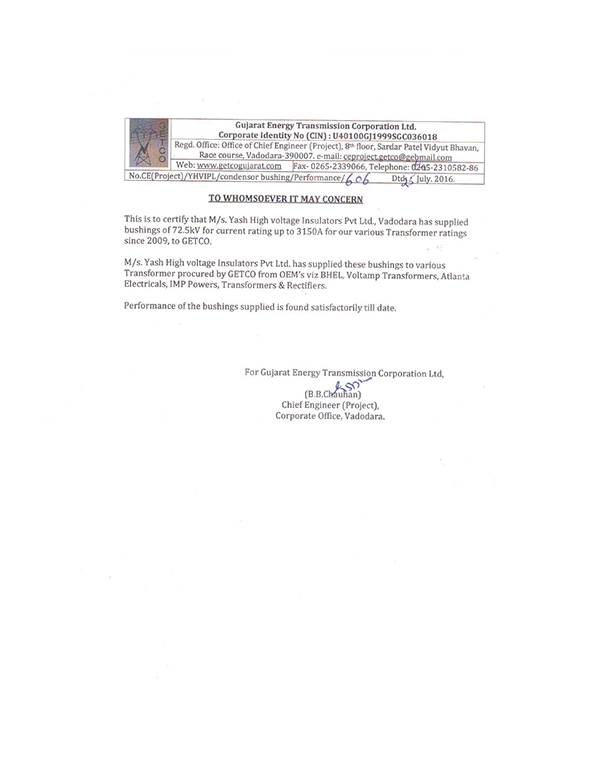

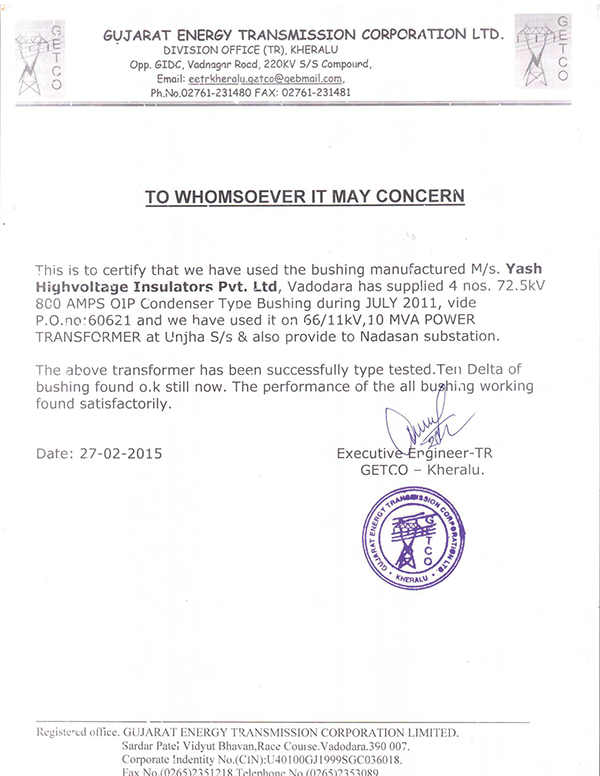

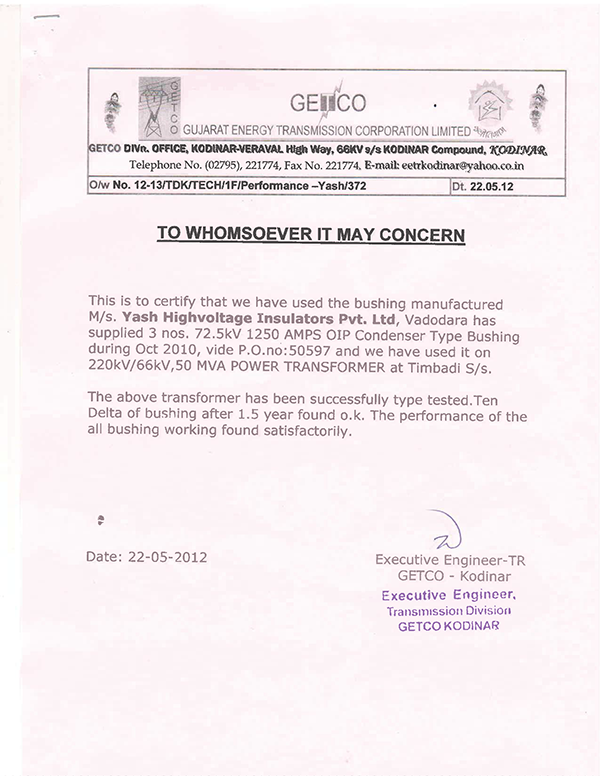

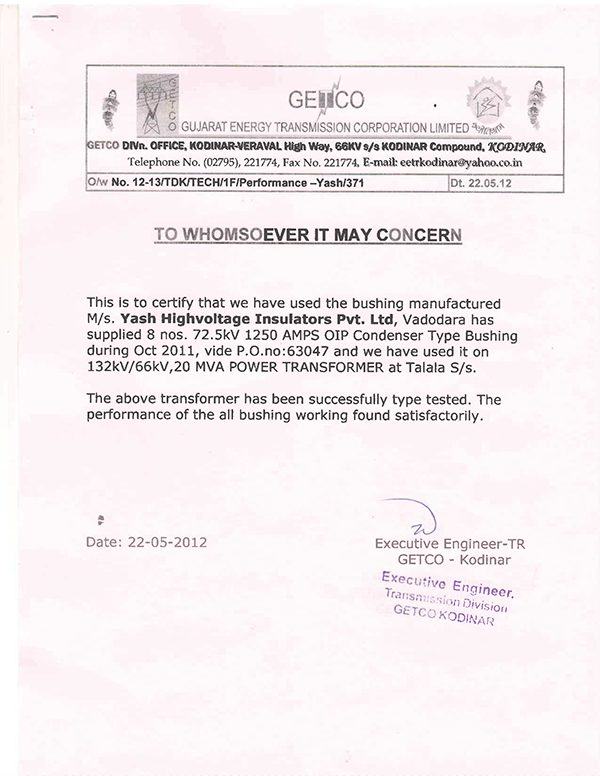

- Manufacturing and field experience of more than 12,000 Bushings

- Computer aided finely graded Capacitive insulation for optimum electrical field distribution

- Partial discharge free and low dissipation factor attributable to stable long-term performance

- Shatter-proof oil end insulator

- High seismic and SC load withstand capacity

- Available with porcelain or composite insulator housing on air-side

- Excellent thermal performance

- Large size oil indicator for better visibility from distance and angles

- Viton material O-rings for oil sealing

- Special terminals available upon on request

- Potential for customization of BCT, oil end length, mounting flange to a large extent

- Exact interchangeability with global reputed makes

- Shortest lead times industry wide

- VCL/VCD/VCS Bushings are High voltage capacitance graded oil-impregnated paper insulated bushings

- The Bushings comply with IEC 60137 standard’s performance requirements for application in power transformers

- The main component of Bushing is the Active part and is manufactured using insulating kraft paper wound around a central tube or solid conductor

- During paper winding, aluminium foils are embedded in paper co-axially at pre-calculated locations to optimise the radial and axial electrical field along the bushing

- After winding, paper core is dried under vacuum at elevated temperatures and subsequently impregnated with high quality vacuum dried and degassed Insulating mineral oil

- Bushing is assembled in a controlled environment and filled under vacuum with vacuum dried and degassed Insulating Mineral oil

- After oil filling, each Bushing is subjected to oil filled over-pressure test for verification of joint sealing

- All bushings are routine tested and type tested in accordance with IEC 60137

- VCL/VCD/VCS Bushings are High voltage capacitance graded oil-impregnated paper insulated bushings

- The Bushings comply with IEC 60137 standard’s performance requirements for application in power transformers

- The main component of Bushing is the Active part and is manufactured using insulating kraft paper wound around a central tube or solid conductor

- During paper winding, aluminium foils are embedded in paper co-axially at pre-calculated locations to optimise the radial and axial electrical field along the bushing

- After winding, paper core is dried under vacuum at elevated temperatures and subsequently impregnated with high quality vacuum dried and degassed Insulating mineral oil

- Bushing is assembled in a controlled environment and filled under vacuum with vacuum dried and degassed Insulating Mineral oil

- After oil filling, each Bushing is subjected to oil filled over-pressure test for verification of joint sealing

- All bushings are routine tested and type tested in accordance with IEC 60137

Download Catalogue (PDF)

Download