At Yash Highvoltage, we believe that education is the bedrock of a brighter future. It's not just about academics; it's about providing a safe, stimulating environment where children can learn, grow, and reach their full potential. With that commitment towards educational advancement and creating a more comfortable and conducive learning environment, we took the initiative to donate much-needed furniture brand-new school benches and wardrobes to Khakhariya School. The initiative made a positive impact on the seating infrastructure for the students and a supportive environment for their studies.

Building a Brighter Future, One Brick at a Time:

Proper sanitation is a critical aspect of any learning environment, especially in a learning environment to promote and foster awareness on hygiene. Recognizing this essential need, Wwe proudly embarked on sponsoring the construction of a new toilet blocks for boys and girls studying in Khakharia School.

This project will equip the school with hygienic and readily accessible facilities, significantly promoting the health and wellbeing of both students and staff.

Beyond corporate responsibility, education fires a deep-seated passion within Mr. Keyur Shah, Managing Director of Yash Highvoltage. He believes every child is like a little seed, bursting with potential just waiting to grow. He says school shouldn't be about just stuffing your head with facts, but about helping kids' imaginations take flight and building a future that is as amazing as their dreams!

We are committed to social responsibility, and supporting education is at the core of our values. We at Yash believe that by illuminating opportunities for learning, we can light the way for a better tomorrow.

It is an honour for Yash Highvoltage Ltd. to be a part of Anand Ashram Charitable Trust's 'ASHAYEIN' project, a remarkable initiative that provides education and support to underserved girl students. We are firmly committed to aligning ourselves with the nation's "Beti Padhao" campaign, recognizing the transformative power of education for girls.

Our commitment to the ASHAYEIN project extends beyond financial support. Mr. Keyur Shah, Managing Director of Yash Highvoltage Ltd. and a devoted champion of girl child education, was recently honored as the Chief Guest at a prestigious event celebrating the project's achievements. His presence not only underscored our unwavering support for this noble cause but also served as a powerful symbol of our dedication to empowering the next generation of women leaders.

Our commitment to the ASHAYEIN project manifests in our dedication to:

Empowering girls from underserved communities with access to quality education

Offering holistic support beyond academic boundaries, encompassing social and emotional well-being

Fostering confidence, independence, and a spirit of leadership in these young girls

Providing financial assistance to ensure girls have access to quality education

Volunteering our time and expertise to mentor and support young girls

Raising awareness about the importance of girl child education

Yash Highvoltage Ltd. is deeply invested in leaving a positive footprint on the communities we serve. We shall remain committed to many such admirable social causes to shaping a prosperous future for all.

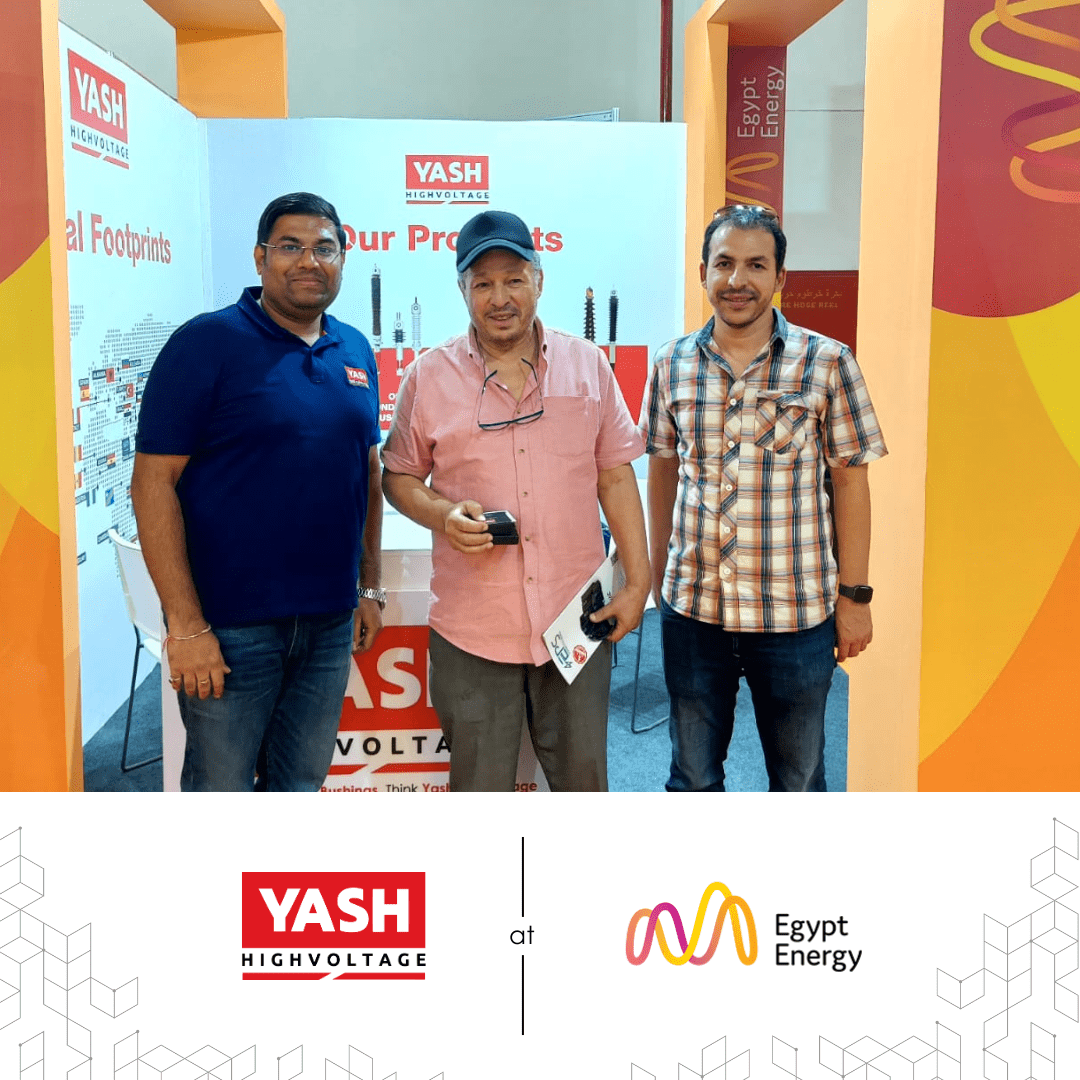

Yash Highvoltage a leading power engineering and specialized high voltage and high current Transformer Bushings manufacturer, took a prominent role at the recently concluded Egypt Energy 2023, the foremost energy event in North Africa. As a significant contributor to the industry's premier gathering, Yash Highvoltage stood out as a key participant, utilizing the expo as a unique platform for networking and envisioning future opportunities.

The exhibition proved to be an outstanding congregation, fostering insightful exchanges among industrialists, peers, prospects, and customers. Yash Highvoltage expresses sincere gratitude to all participants for their invaluable contributions to the event's resounding success.

As the provider of world-class Transformer Bushing Solutions for the High Voltage Field, Yash Highvoltage exhibited its cutting-edge products and services, making a lasting impact. Mr. Abhijit Ballawar, the company representative at the event, underscored the crucial role of such events in networking and engaging with industry experts, essential for the continued growth of the sector.

Yash Highvoltage found the All Egypt Energy 2023 to be a rewarding experience and eagerly anticipates taking part in more such extraordinary events in future.

Yash Highvoltage Ltd., a leading power engineering and specialized high voltage and high current Transformer Bushings manufacturer, had a notable presence at the recently concluded All Energy Expo 2023 – the largest gathering of renewable energy professionals and most anticipated clean energy event in Australia. The event served as a unique platform for networking and exploring future possibilities in the industry.

The exhibition proved to be an exceptional gathering, fostering informative exchanges among industrialists, peers, prospects, and customers. Yash Highvoltage extends sincere gratitude to all participants for contributing to the event's success.

This year at the All Energy Expo, Melbourne Convention and Exhibition Centre, Yash Highvoltage showcased its latest products and services, innovations and upcoming plans making a significant impact. Mr. Divyanshu Saxena, our company representative at the event, emphasized the value of such events focused on the latest technology, information, and trends crucial for industry growth.

In summary, Yash Highvoltage had an enriching experience at the All Energy Expo 2023 and eagerly anticipates participation in future events of similar significance.

Our cutting-edge 115kV 800A 534CT Oil Impregnated Paper Bushings (in accordance with IEEE Standard) are prepared to undergo a comprehensive series of testing procedures. These steps are taken to ensure their impeccable performance prior to their ultimate dispatch.

The image depicts our IEEE Bushing undergoing Capacitance and Tan Delta Tests. Following this, it will undergo the Dry Lightning Impulse Test to determine its resilience against lightning strikes, along with various other High Voltage Tests.

To enable a speedy process of testing and to meet the requirements of our discerning customers globally, Yash Highvoltage has developed a state-of-the-art 550kV EHV Test lab with ultra-modern testing equipment sourced from world-renowned brands with a high level of measuring accuracy and reliability, to perform all routine and special tests.

After the testing of the IEEE Bushings is completed, these components will commence their journey to a renowned transformer manufacturer in the United States. We're thrilled to be part of the backbone that keeps the world energized.

Over the course of the past two decades Yash Highvoltage has established a niche reputation in the high voltage infrastructure sector. Renowned for our unwavering dedication to innovation quality and reliability, we have delivered exceptional bushing solutions worldwide.

Continuing with our progressive ideology we are delighted to announce a significant addition to our team. We take pleasure in introducing Mr. Chris Gerber, a seasoned professional with over twenty years of experience in the Transformer and Energy industry, as our Chief Strategy Officer, responsible for overseeing operations in the EMEA region.

Mr. Chris Gerber, with his profound experience, brings a wealth of expertise and an exemplary track record to Yash Highvoltage. Throughout his career, he has held pivotal positions at prestigious private equity-owned and public companies within the Energy sector.

His extensive background includes valuable contributions to Eskom Ltd, the South African power utility, Royal Smit Transformers of the German-based SGB-SMIT Group, ETD Transformers in the Czech Republic, CG Holdings and Power Systems and Genesis Consulting.

Demonstrating exceptional proficiency, he has excelled in a range of roles encompassing operational, strategic, consultative, executive and non-executive board capacities. As a respected speaker and moderator at international conferences, he shares valuable insights on the impact of European carbon emission policy, strategy and legislation, specifically on companies in the energy industry. Additionally, he has authored several published articles focusing on mergers and acquisitions in the transformer industry, oil and gas and electric mobility.

Underscoring his professional aptitude are his educational credentials. He holds a Bachelor's degree in Strategic Marketing Management from the distinguished University of Pretoria in South Africa and a Master's degree in Industrial Management from VUB in Belgium that further reinforces his capability as a leader in the industry.

We welcome Mr. Chris Gerber to the Yash Highvoltage family and are confident that his expertise, strategic insights and leadership will help the organisation to achieve path-breaking success.

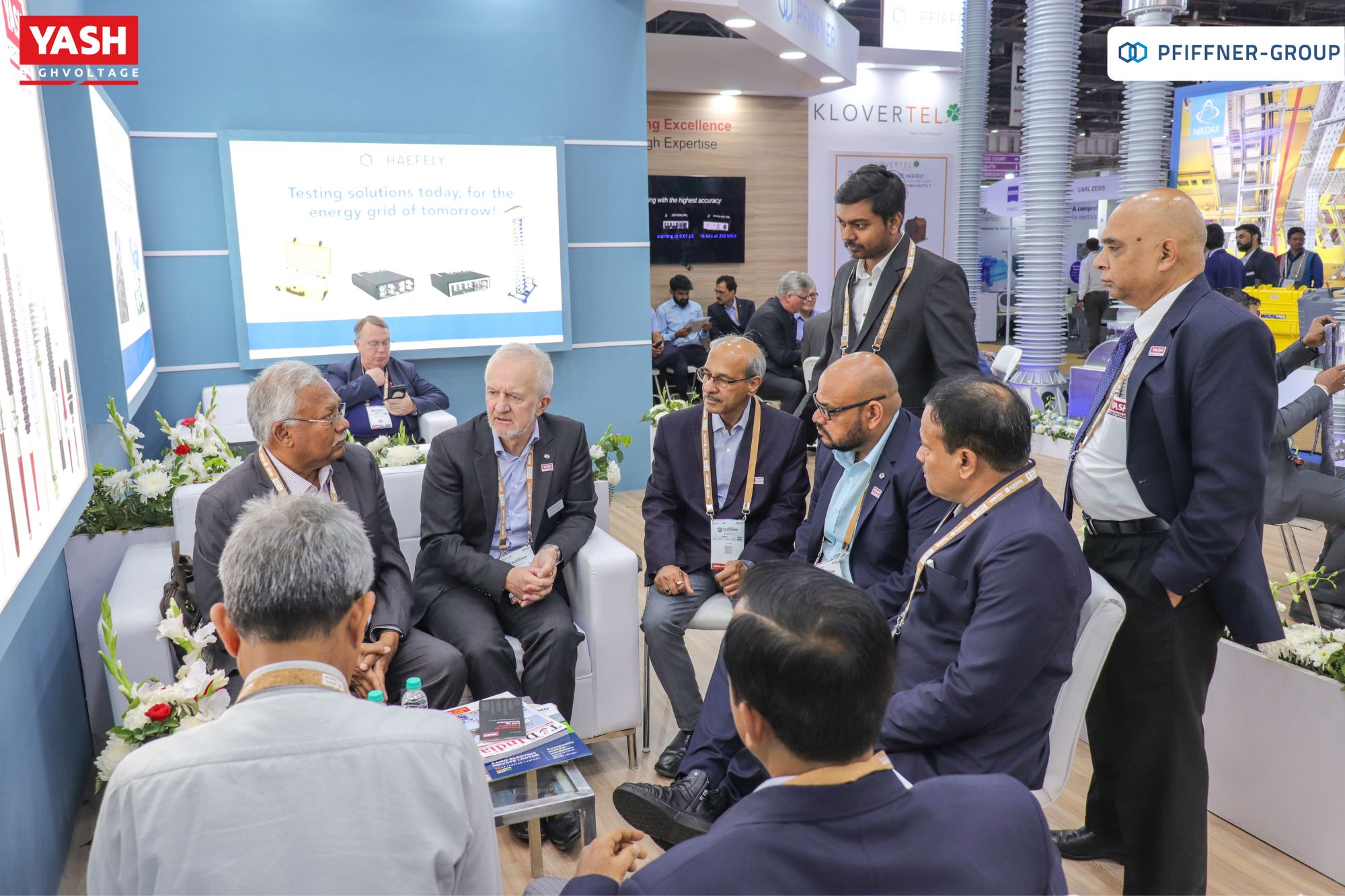

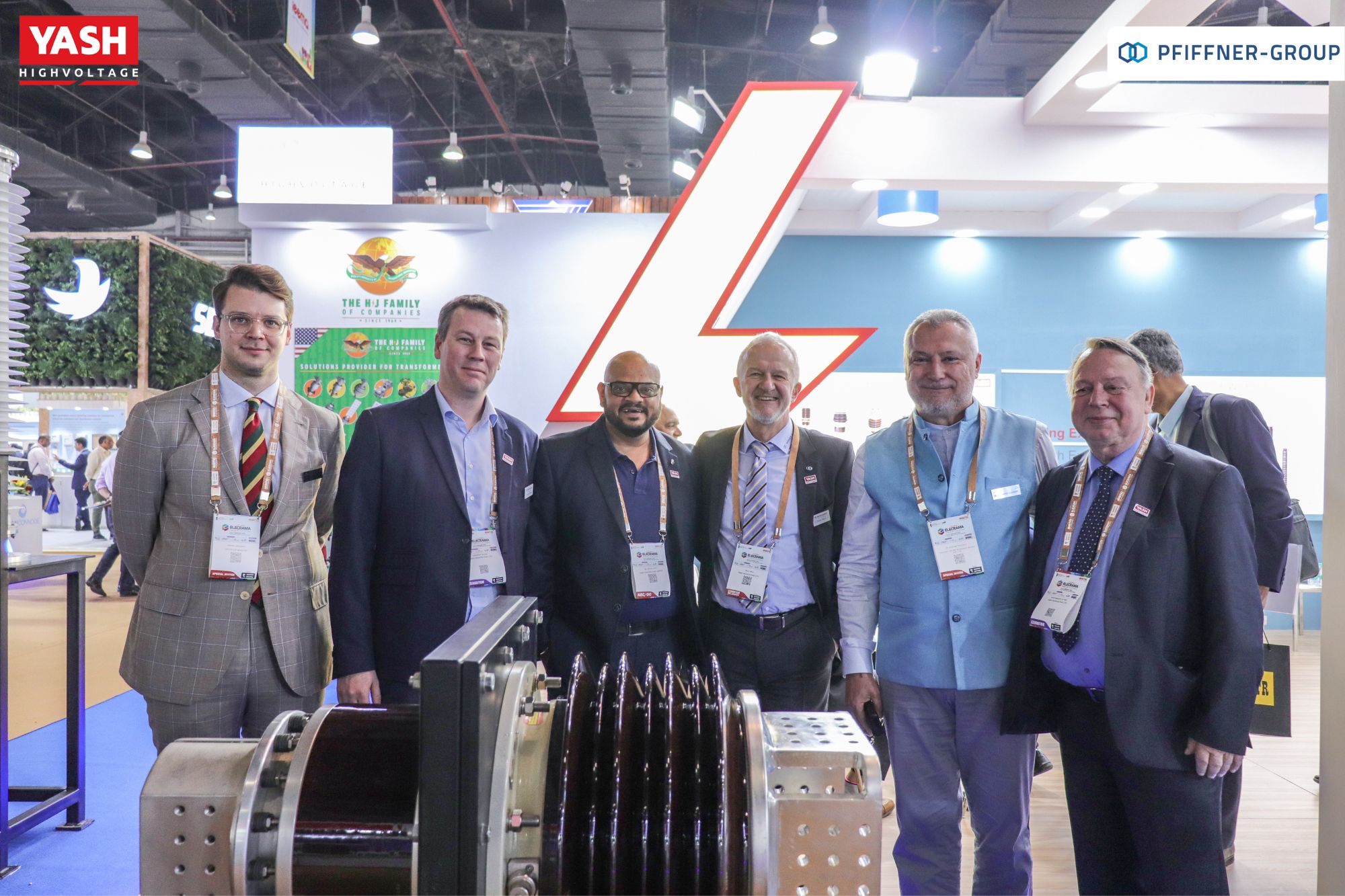

Yash Highvoltage, a prominent electrical equipment manufacturer, had a remarkable experience at the recently concluded #ELECRAMA 2023 expo, India's most significant and prestigious electrical and electronics industry event. The event brought together prominent players from the power sector, and Yash Highvoltage, along with Pfiffner, Moser Glaser, Haefely AGC, The H-j Family, and Klovertel, had the opportunity to engage in informative and beneficial conversations with distinguished industrialists, peers, prospects, and customers from the electrical and allied industries.

Get the Full experience of Elecrama Aftermovie >> Click Here

The event was a unique and unparalleled gathering that provided an excellent platform for exploring new horizons and paving the way for the industry's future. Attendees actively engaged in the event, resulting in a fruitful and enlightening experience. Yash Highvoltage expressed sincere appreciation to all attendees for their contribution to the success of the event.

As a leading electrical equipment manufacturer, Yash Highvoltage had the opportunity to showcase their latest products and services, and their presence at the expo was a resounding success. In addition, the inauguration ceremony for Yash Highvoltage's 245 kV OIP and 245 kV RIS was a truly prestigious affair, presided over by Mr. R.K. Tyagi, Director (Operations) at Powergrid India.

Furthermore, Yash Highvoltage's Managing Director had an opportunity for a thought-provoking discussion with Shri R.K. Singh, the esteemed Power & Renewable Energy Minister of India, making the event even more special and significant.

The company's representatives emphasized the importance of attending such events as they provide a valuable opportunity for networking and meeting with industry experts, which is crucial for the growth and development of the industry. This event was especially important and special for every company that participated as it took place after a two-year pandemic hiatus.

In conclusion, Yash Highvoltage had an electrifying experience at the #ELECRAMA 2023 expo and expressed eagerness to attend future events of such caliber.

We had the pleasure of hosting our partners and friends from MGC Moser-Glaser AG, Mr. Laurent Vlesik and Mr. Boris Nissle, for a three-day visit last week. The visit was filled with productive discussions and planning for sustainable growth in the future, as well as opportunities for technological interactions and compliance checks. In addition to the business-focused activities, we also had the chance to enjoy each other's company and create some fun and memorable experiences.

On behalf of our team at Yash Highvoltage, we would like to extend our sincerest thanks to Mr. Vlesik and Mr. Nissle for taking the time to visit us. We value our partnership with Moser Glaser and look forward to many more such interactions in the future. KEYUR SHAH, Nirav Patel, Divyanshu Saxena, Jatin Tyagi, Umesh Bhalerao, Nitin Kulkarni, Gautam Nikam and Pramod Rao

all participated in the visit and had a great time working with our partners from Moser Glaser.

In November this year, Yash Highvoltage Ltd. was one of the proud sponsors of the 13th National workshop on Emerging Technologies (NWET-2022) & All India Power Engineers Meet (AIPEM-2022) with a focus on "Grid Modernization & Digitization - A step towards a Green Technology" on 24th - 26th Nov 2022 at Bhubaneswar.

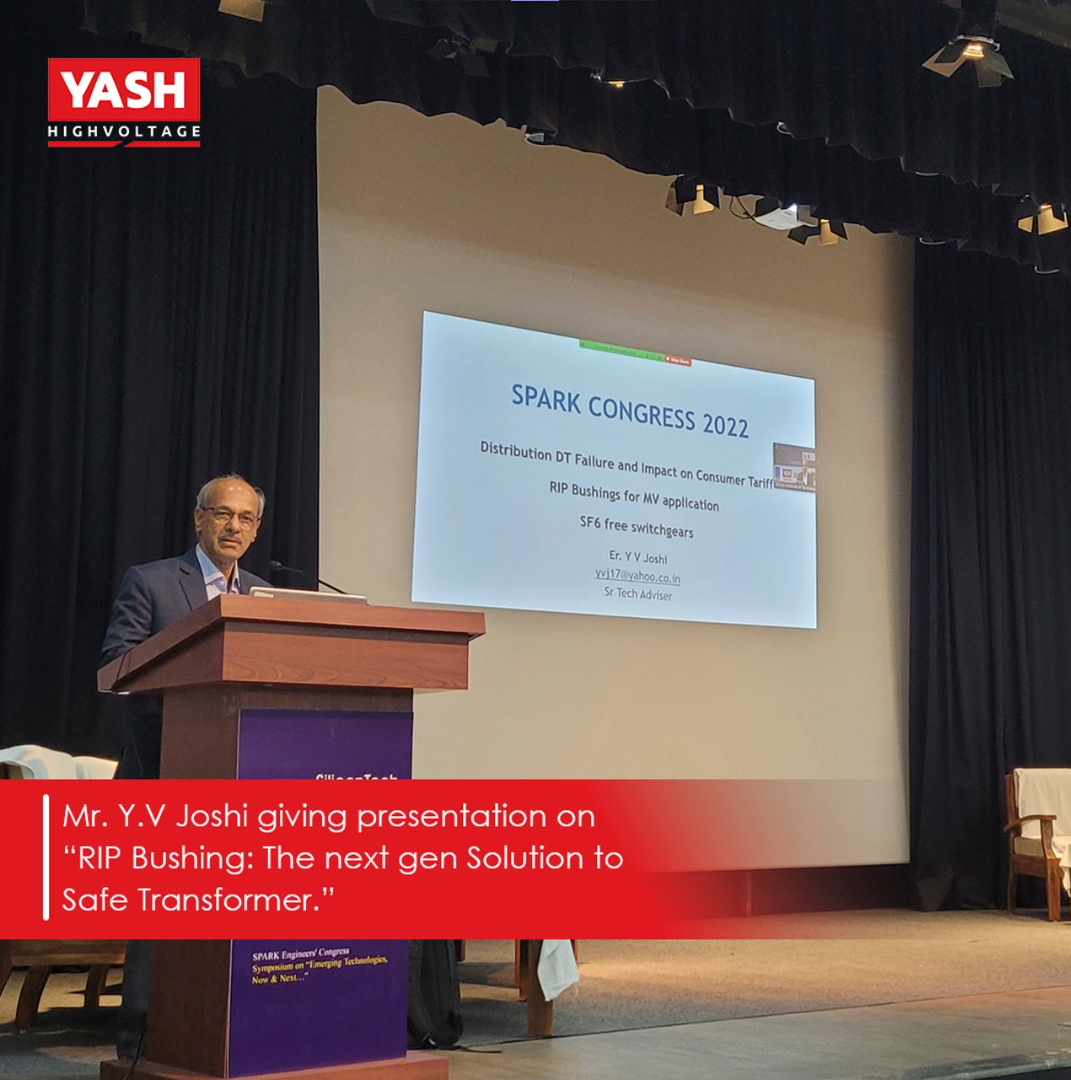

Senior technical experts from the Yash Highvoltage, Mr. Pramod Rao and Mr. Y V JOSHI were invited as speakers to share their experiences and thoughts on emerging technologies in the power & distribution industry.

Mr. Pramod Rao delivered an in-depth session on Emerging Trends in Transformer Bushings technologies and the latest on dry Resin Impregnated Paper (RIS) bushings, and Mr. Joshi as part of the NWET Expert Panel discussions shared his views on various topics including RIP Bushing: The next-gen Solution to Safe Transformer, and Techno-commercial Impact for DTR failure.

Four days at the event were quite capitalizing as our team member MR. Abhishek Gupta & Mr. Sanjay Vyas interacted with students to share with them about future technologies in Power Engineering at the Silicon Institute of Technology along with many stalwarts from the Indian Power Industry.

All in all, it was an enriching technological experience and we thank SPARK Group, Mr. PRASANTA PATTANAIK as well as the Silicon Institute of Technology (SIT), Bhubaneswar for the opportunity to be a part of this mega event.

KEYUR SHAH Nirav Patel Anindya Basu Abhijit Ballawar Divyanshu Saxena Jatin Tyagi Dishang Shah Yogesh Bhame Gautam Nikam

Moving towards an inclusive, safe, and grievance-free environment for all women staff, we organized a brief session & meeting on PoSH - Prevention of Sexual Harassment on Women to ensure awareness of women's safety at the workplace.

We at Yash Highvoltage are aligning our visions and the culture toward a Safer & Healthier tomorrow for all our members and stakeholders.

Mr. Yash Pawar delivered an excellent session covering many predominant points of #PoSH.

All credit to our Management, HR & Admin team for organizing such an interactive and eye-opening session on PoSH & a big thank you to our consultant Mr. Yash Pawar for delivering the session.

KEYUR SHAH Nirav Patel Rachna Naik Nimbalkar

Rishabh Pandya Riya Parikh Siju Webson

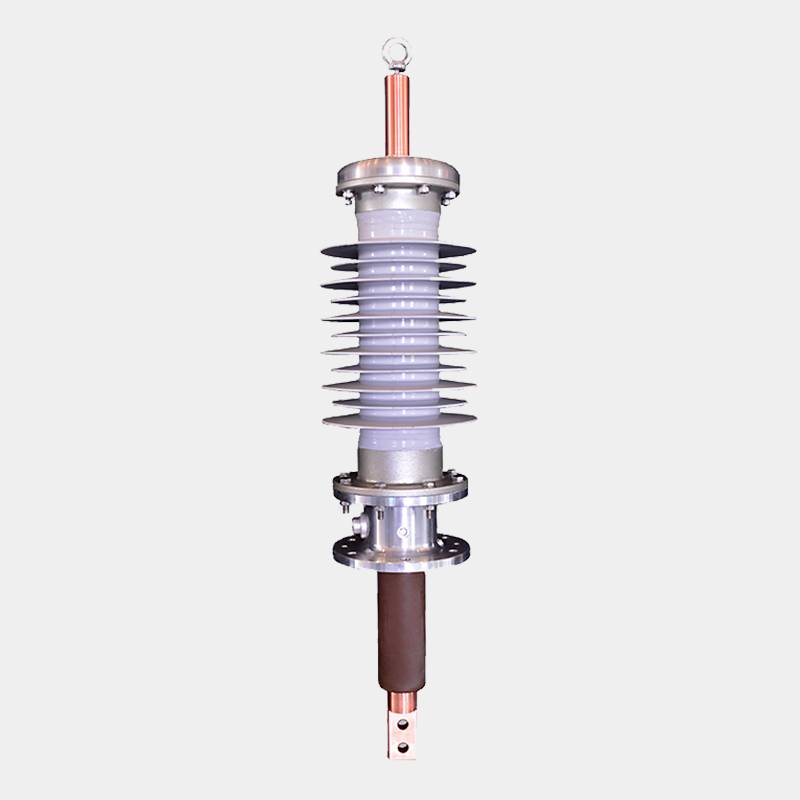

Yash Highvoltage is proud to announce a new set of 72.5 kV 800 A 600 CT OIP Bushings custom made for a prestigious customer in Latin America. Oil Impregnated Paper (OIP) Condenser Bushings, are widely used in the high voltage transmission industry due to their durability and reliability.

The production process for OIP bushings involves winding Kraft paper tightly around a conductor, adding layers of aluminium foil, and then drying the result under heat and vacuum to remove moisture. The final product is then impregnated with specially processed transformer oil.

In addition to the standard OIP bushings, Yash Highvoltage also offers customized solutions for both wall-through and Oil-Oil applications inside transformer cable boxes. Our team is dedicated to meeting the needs of our customers, and we have supplied specialized OIP bushings to numerous clients in India and around the world.

For more information on our OIP bushings and to inquire about our services, please contact us at sales.int@yashhv.com and sales@yashhv.com.

Yash Highvoltage Ltd. is a leading manufacturer of high voltage and high current transformer bushings, with 20 years of experience in the industry. We have a strong track record of producing top-quality products, with over 27,000 bushings performing exceptionally well in various locations around the world.

We are excited to announce that a new set of 115 kV OIP Condenser Bushings, built to IEEE standards and complete with voltage tap and grey porcelain insulators, is now available for the US market. These bushings are set to embark on an 8000 mile journey across the Atlantic to reach their destination.

If you are interested in learning more about our transformer bushings or have any inquiries, please don't hesitate to contact us at sales.int@yashhv.com or sales@yashhv.com. At Yash Highvoltage, we pride ourselves on producing top-quality products and providing excellent customer service.

The Egypt Energy Expo was a huge success for us, with a great turnout of prospects and customers visiting our booth over the course of the three-day event. It was a valuable opportunity to learn about the expanding power infrastructure in Egypt and meet with influential figures in the Egyptian power and transmission industry.

We would like to express our gratitude to everyone who took the time to visit us at the expo. If you have any inquiries, please don't hesitate to reach out to us at sales.int@yashhv.com or sales@yashhv.com.

Sincerely,

Abhijit Ballawar, Nirav Patel, KEYUR SHAH, Divyanshu Saxena

The Retrofit & Services Division of Yash is pleased to announce the appointment of Mr. Sanjay Vyas as its new Country Head. With over 35 years of experience in the services sector for transformer accessories and related products, Mr. Vyas brings a wealth of industry knowledge to the role. Throughout his career, he has worked with several renowned companies, including CTR Manufacturing Industries Ltd. in Pune, Jyoti Limited in Vadodara, Insulators and Electricals Company (HDC Ltd.) in Mandideep, Larsen & Toubro Ltd in Mumbai, Controls & Switchgear Company in Delhi, and Cooper Bussmann India Pvt. Ltd. in Pondicherry.

We believe that Mr. Vyas will be a valuable addition to the Yash team and will contribute significantly to the growth and success of the company. We look forward to working with him and taking advantage of his expertise.

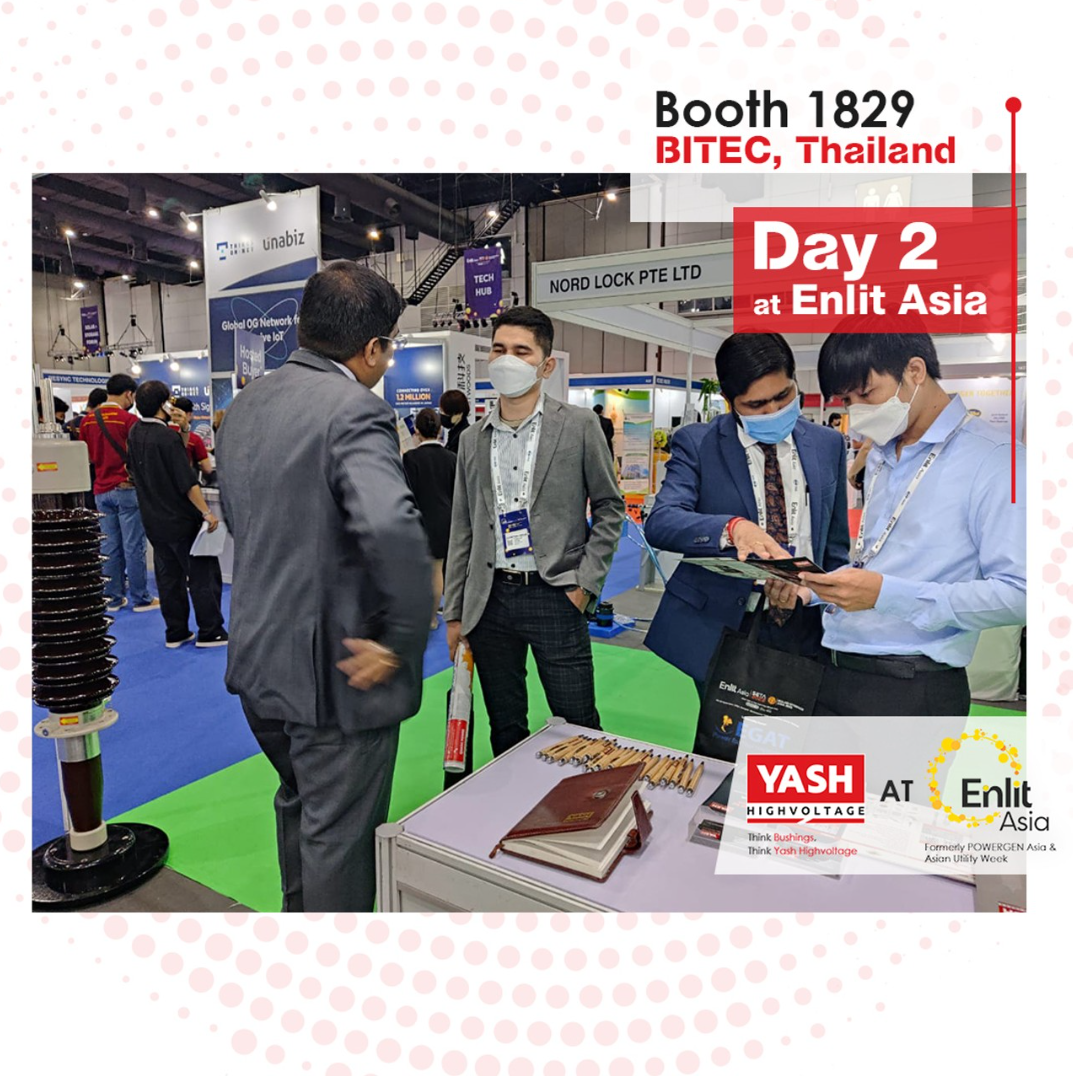

Enlit Asia 2022 was a successful event for us, with a large number of walk-ins on the first day and productive meetings and networking on the second and third days. We received many inquiries about our transformer bushings technologies and had a great time meeting new prospects and engaging in productive conversations. Yash Highvoltage would like to thank all of the patrons and prospects who visited us at the event and look forward to seeing them at the next expo.

As part of the Knowledge Sharing series at Yash Highvoltage, we recently held a detailed seminar on the emerging technologies of transformer bushings, specifically Resin Impregnated Synthetic (RIS) Condenser Bushings, for one of the prominent utilities in Western India. The seminar was led by Mr. Pramod Rao, Sr. Technical Advisor at Yash Highvoltage Ltd., and facilitated by Divyanshu Saxena and Yogesh Bhame.

During the session, attendees received an in-depth presentation on the technological advancements in RIS bushings, including the advantages of using them, best practices for application, manufacturing methods, and technical explanations of the RIS condenser bushing technology. Both the customer and our team greatly benefited from this interactive session and we are grateful for the opportunity to share our knowledge and expertise.

Yash Highvoltage Ltd. is proud to offer an extensive range of OIP (Oil impregnated Paper) bushings that are suitable for use in both wall-through applications and Oil-Oil applications inside transformer cable boxes. We are pleased to announce that we have recently completed testing and quality control for a set of Oil-Oil transformer bushings that are now ready for dispatch.

These bushings, which are rated at 72.5 kV 800 A 100 CT, will be installed at a prestigious PSU petroleum and gas producer company in India. We are confident that our bushings will provide reliable and efficient performance for our customer.

If you have any questions or would like more information about our OIP bushings, please don't hesitate to contact us at sales@yashhv.com. We are always happy to assist with any inquiries you may have.

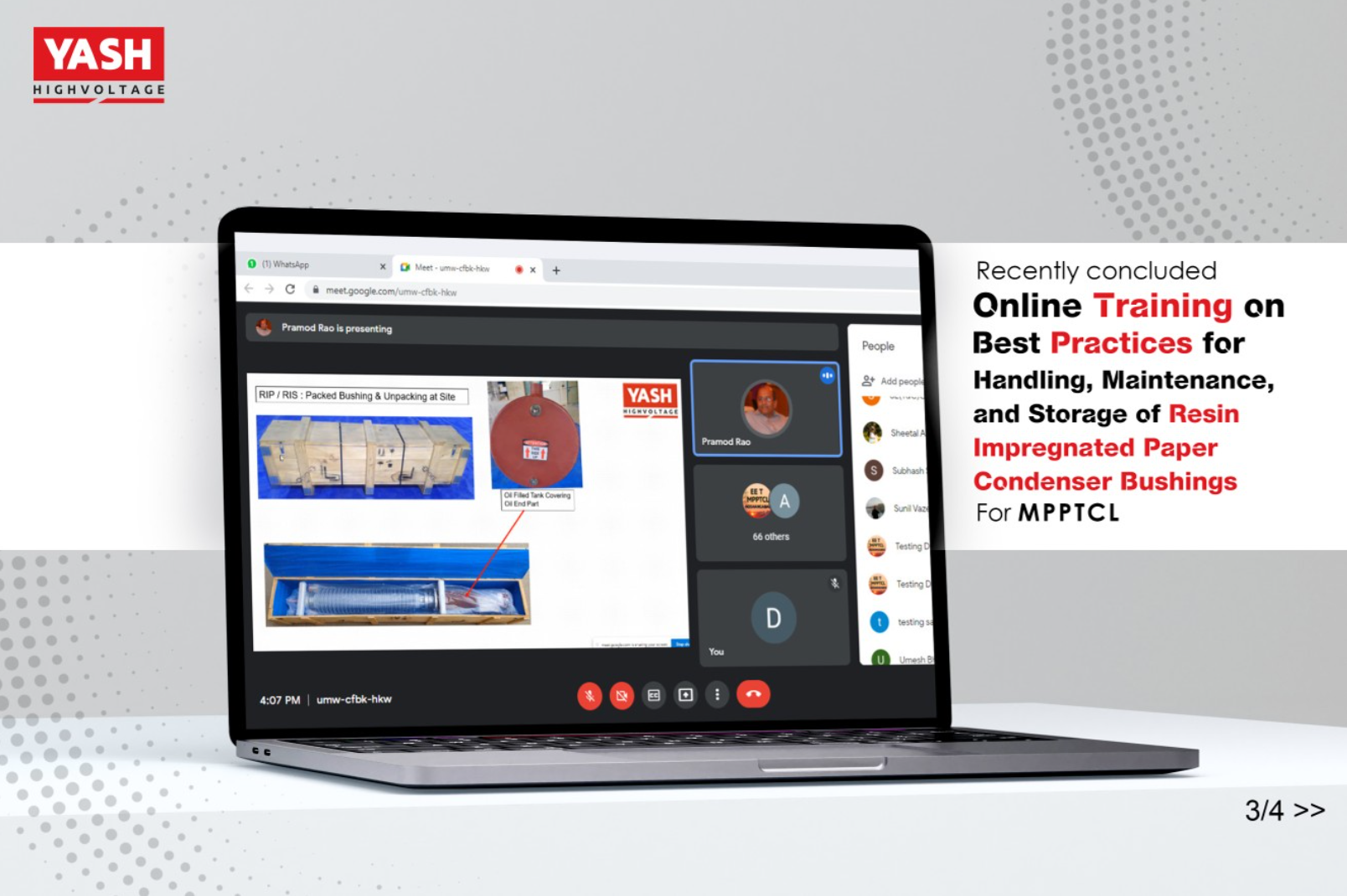

Recently, Yash Highvoltage had the pleasure of hosting a virtual knowledge-sharing session for the esteemed engineers of Madhya Pradesh Power Transmission Company Limited (MPPTCL). The session focused on best practices for the handling, maintenance, and storage of resin impregnated paper (RIP) condenser bushings.

During the training, our team covered a range of topics, including key elements of RIP bushings, proper installation techniques, and tips for testing and condition monitoring. The session concluded with an interactive Q&A, during which attendees had the opportunity to ask questions and clarify any points of confusion.

More than 70 members of MPPTCL participated in the training, and both teams found the session to be highly enlightening and beneficial. At Yash Highvoltage, we are committed to sharing our knowledge and expertise with all stakeholders, and we look forward to hosting more training sessions in the future. We are always available to assist end users and OEMs with their specific needs and questions.

We would like to extend our heartfelt thanks to the team at MPPTCL for the opportunity to collaborate and for making this training a success.

KEYUR SHAH Nirav Patel Pramod Rao Anindya Basu Gautam Nikam Nitin Kulkarni Abhishek Gupta Divyanshu Saxena

We are pleased to announce that Yash Highvoltage was recently featured in the "Leaders of Change" section of the Independence Day Special Coverage of the Times of India. It was a moment of pride for everyone at our company to be recognized in such a prestigious publication.

The in-depth coverage included a look at the journey of Yash Highvoltage, highlighting our strength and resilience during the pandemic period, as well as the innovative work we have done and our future endeavors. It also featured a brief interview with our Managing Director, KEYUR SHAH.

If you missed the chance to read the editorial in the Special Independence Day edition of the Times of India, you can find it below. We are grateful to the Times of India for this opportunity and for recognizing the important work that we do at Yash Highvoltage.

A Journey is left uncelebrated if it's not with all the ones who have played a part in it, We heartily celebrated Yash Highvoltage's 20th Annual Day, reminiscing all the collective efforts, love, care, dedication & hard work that has made this a successful ride.

> Watch the Full Video on our Youtube Channel <

Beginning with the Lamp Lighting Ceremony which was followed by Speeches from the dignitaries, Team building and bonding activities, A Fun Yoga session & an Award Ceremony to recognize all the Efforts.

A fun-filled day that not only celebrated the past but also accelerated the coming bright years of Yash Highvoltage, we joyously appreciate the presence of all of us who make Yash Highvoltage, What it is.

KEYUR SHAH Nirav Patel Jatin Tyagi

Gautam Nikam Umesh Bhalerao Nitin Kulkarni Rachna Naik Nimbalkar Rushi Shah Sanjay Vyas Pramod Rao Anindya Basu Twinkle Shah

Divyanshu Saxena Abhishek Gupta Dishang Shah Abhijit Ballawar Darshan Patel Vandeepsinh Parmar Bharat Chauhan Hitesh Motvani Preet Lakharia Nikita Karkar Siju Webson Riya Parikh chandan kumar Rohan Pawar Urvish Mehta Nikhil Prajapati Bibha Jha Mishra

At Yash Highvoltage, we understand that the key to a successful business is not just about making sales, but also about taking care of customers after the sale is complete. That's why we have implemented a range of after-sales services, including onsite training and awareness sessions for our customers. These sessions are designed to educate our customers on the best practices for handling and installing our bushings.

Recently, we had the opportunity to hold one of these sessions at a customer site. Our engineer provided an in-depth training on our Resin Impregnated Paper Bushings, covering the proper techniques for handling, unpacking, and installing the bushings. The session also included a list of do's and don'ts to ensure that our customers get the most out of their purchase.

The engineers and technicians at the customer site were extremely satisfied with the comprehensive training and learning session. At Yash Highvoltage, we are dedicated to providing the best possible service and support to our customers, and we are always looking for ways to improve and enhance their experiences.

Yash Highvoltage has completed production on a new batch of 170kV 800A 300 BCT Oil Impregnated Paper (OIP) Condenser Bushings with Silicone insulators, which are set to embark on a 4000-mile journey to Italy's "Italian Railways." These bushings will be used by one of the oldest transformer and inductive construction element manufacturers in the country.

The OIP condenser bushings are made with high-quality Kraft paper wound tightly around a conductor and layered with aluminum foil. The resulting product is then dried under heat and vacuum to remove moisture and impregnated with specially processed transformer oil. The use of hollow silicone insulators adds an additional level of durability to the finished product.

Yash Highvoltage is based in Vadodara, India, and we welcome inquiries from transformer manufacturers and power developers around the world, including the USA, LATAM, ASEAN, Canada, Europe, Africa, the Middle East, and other markets.

For more information, please contact us at sales.int@yashhv.com or visit our website at www.yashhv.com.

We were thrilled to host the "Power Transformer Division Meet" for the Indian Electrical & Electronics Manufacturers' Association (IEEMA) at our Yash factory premises. It was a true pleasure and privilege to bring together such a prestigious group of friends and peers from the power and transformer industry, particularly after such a long period of pandemic-induced separation.

We would like to express our heartfelt thanks to all of the delegates who participated in the meeting, either in person or virtually. Your presence helped to make the event a resounding success, with productive discussions, valuable networking opportunities, and even some light-hearted moments of laughter. >Watch the Full video on our Youtube Channel<

We were honored to have the following esteemed individuals in attendance: KEYUR SHAH, Nirav Patel, Gautam Nikam, Anindya Basu, Anand Sharma, Abhijit Ballawar, Jatin Tyagi, Yogesh Bhame, Divyanshu Saxena, Neeraj Goyal, Ruchir Mayank, Imteyaz Siddiqui, Abhishek Gupta, Sameer Gaikwad, Prakash R and Deepak Srivastava. Thank you all for your contributions and for helping to make the "Power Transformer Division Meet" a memorable and successful event.

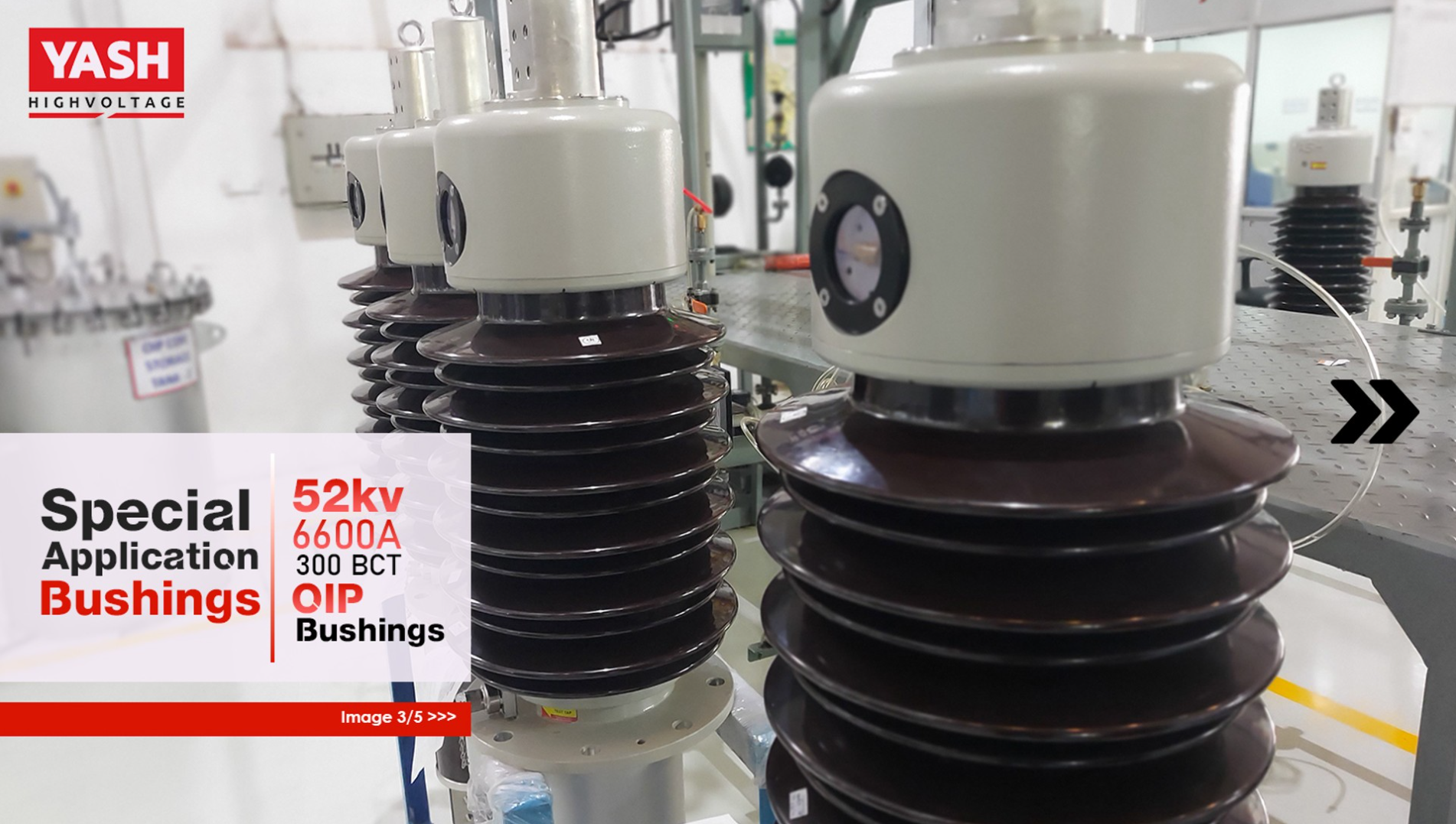

Yash Highvoltage is pleased to announce that we recently delivered a bulk order of 52kV 6600A 300BCT OIP Condenser Bushings to a renowned transformer OEM in India. These bushings will be used in state-of-the-art STATCOM projects for POWERGRID of India (PGCIL), which aims to improve grid voltage stability through reactive power compensation and ensure constant voltage and frequency for uninterrupted power.

It is an honor for Yash Highvoltage to be able to contribute to these innovative projects and the progress of our nation through our specialized bushings solutions for the power industry. We are committed to constantly innovating and deploying our expertise to help bring reliable and high-quality power to consumers.

For more information on our products and services, please visit our website at www.yashhv.com or contact us at sales@yashhv.com.

On the occasion of the IEEMA Power Transformer Division meeting at the Yash factory, we were delighted to have the opportunity to host such a prestigious gathering of colleagues and friends from our industry. It was a pleasure to finally be able to come together in person after such a long break due to the ongoing pandemic.

We would like to express our heartfelt thanks to all members of the transformer division for joining us, whether in person or virtually. We are also grateful to the team at IEEMA for entrusting us with the responsibility of hosting this event.

We were honored to have the following esteemed individuals in attendance: KEYUR SHAH, Nirav Patel, Anindya Basu, Gautam Nikam, Abhijit Ballawar, Divyanshu Saxena, Yogesh Bhame, Jatin Tyagi, Imteyaz Siddiqui, Neeraj Goyal, Ruchir Mayank, Prakash R, Anand Sharma, Deepak Srivastava and Sameer Gaikwad. Thank you for making this event such a success.

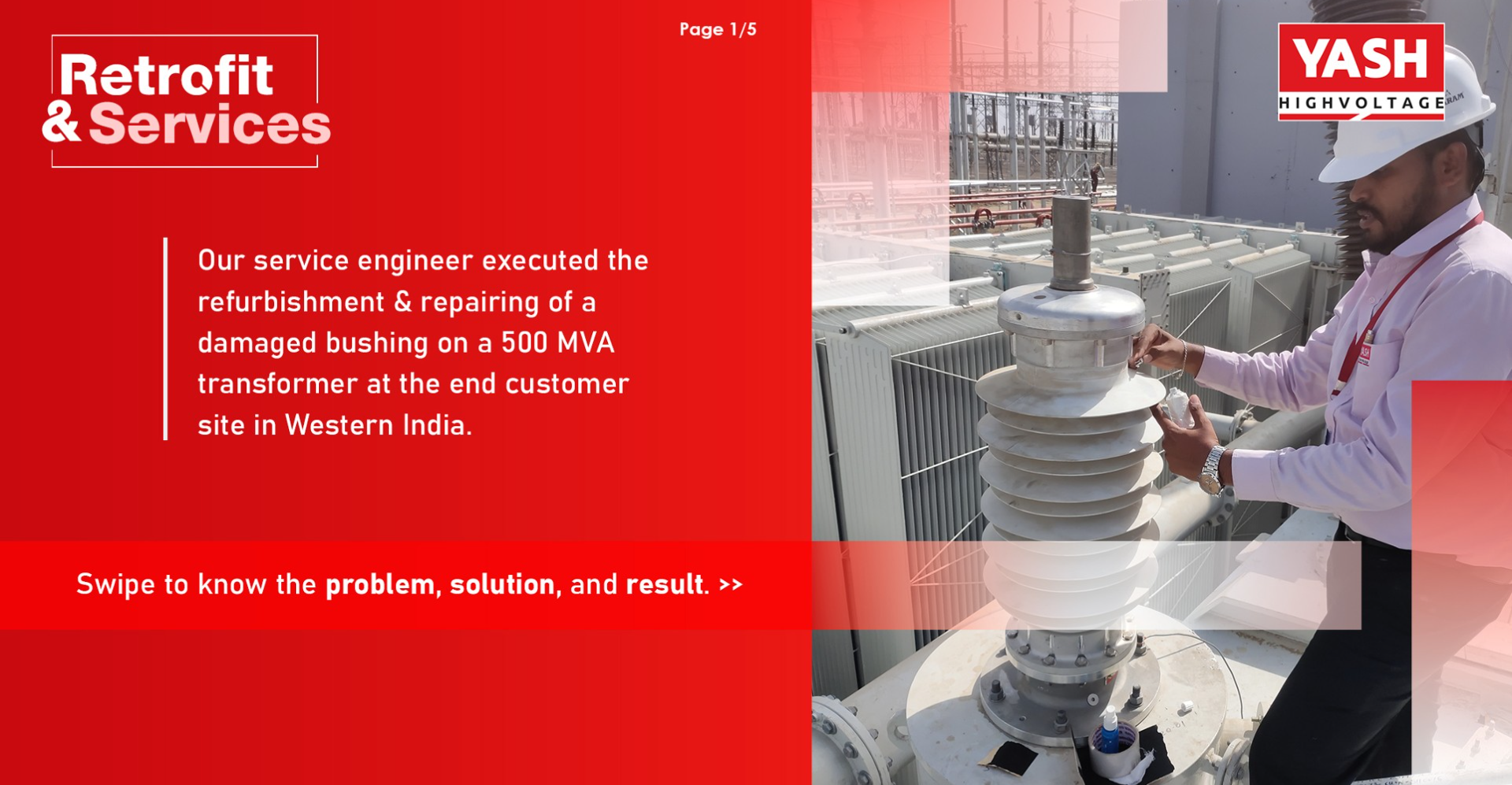

Yash Highvoltage has established itself as a reliable supplier of standard design IEC/IEEE bushings and a comprehensive solution provider for retrofit and repair services for transformer bushings of any make. With more than 25,000 transformer bushings supplied for use up to 245kV, our team has the expertise and experience to handle any retrofit or repair project.

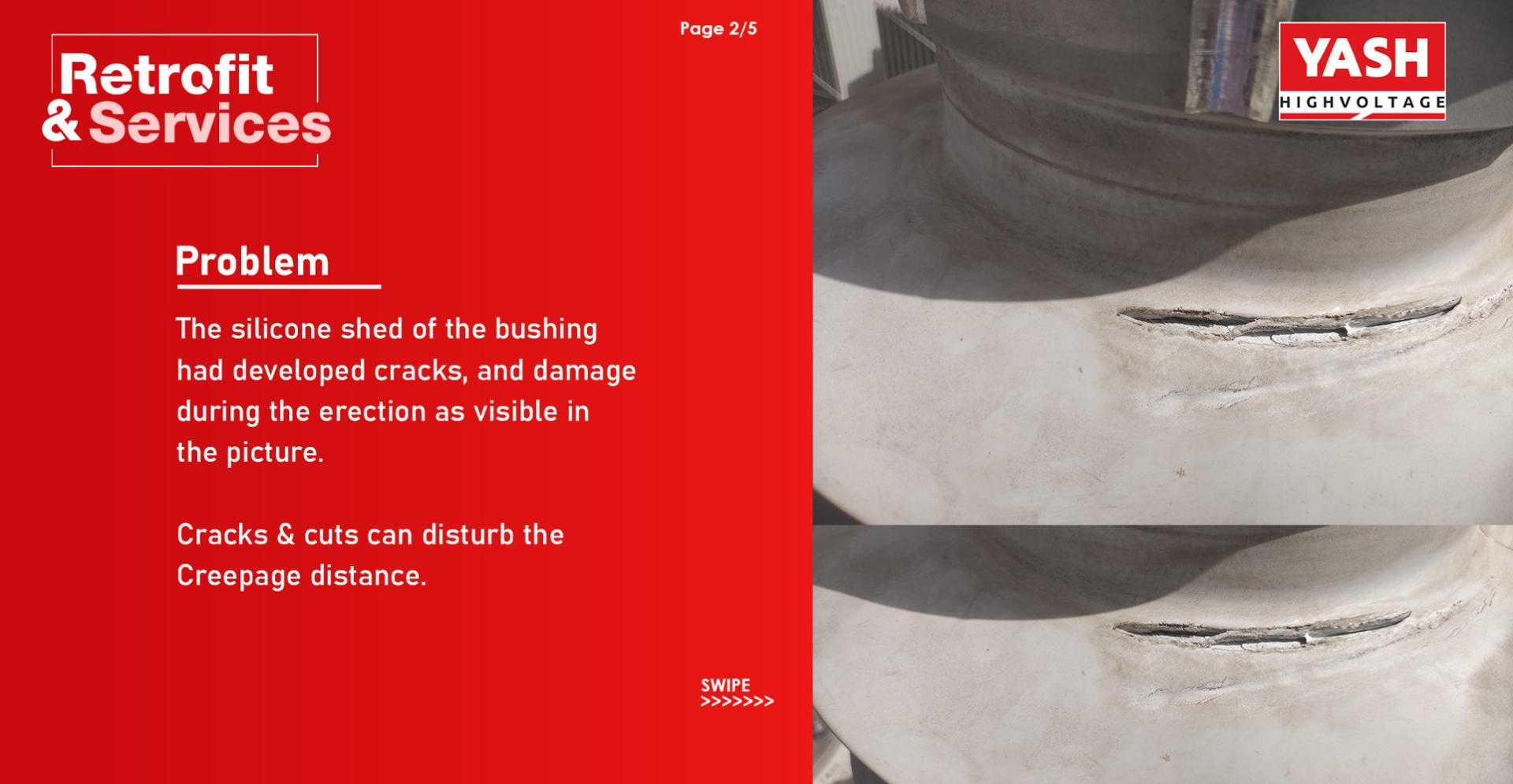

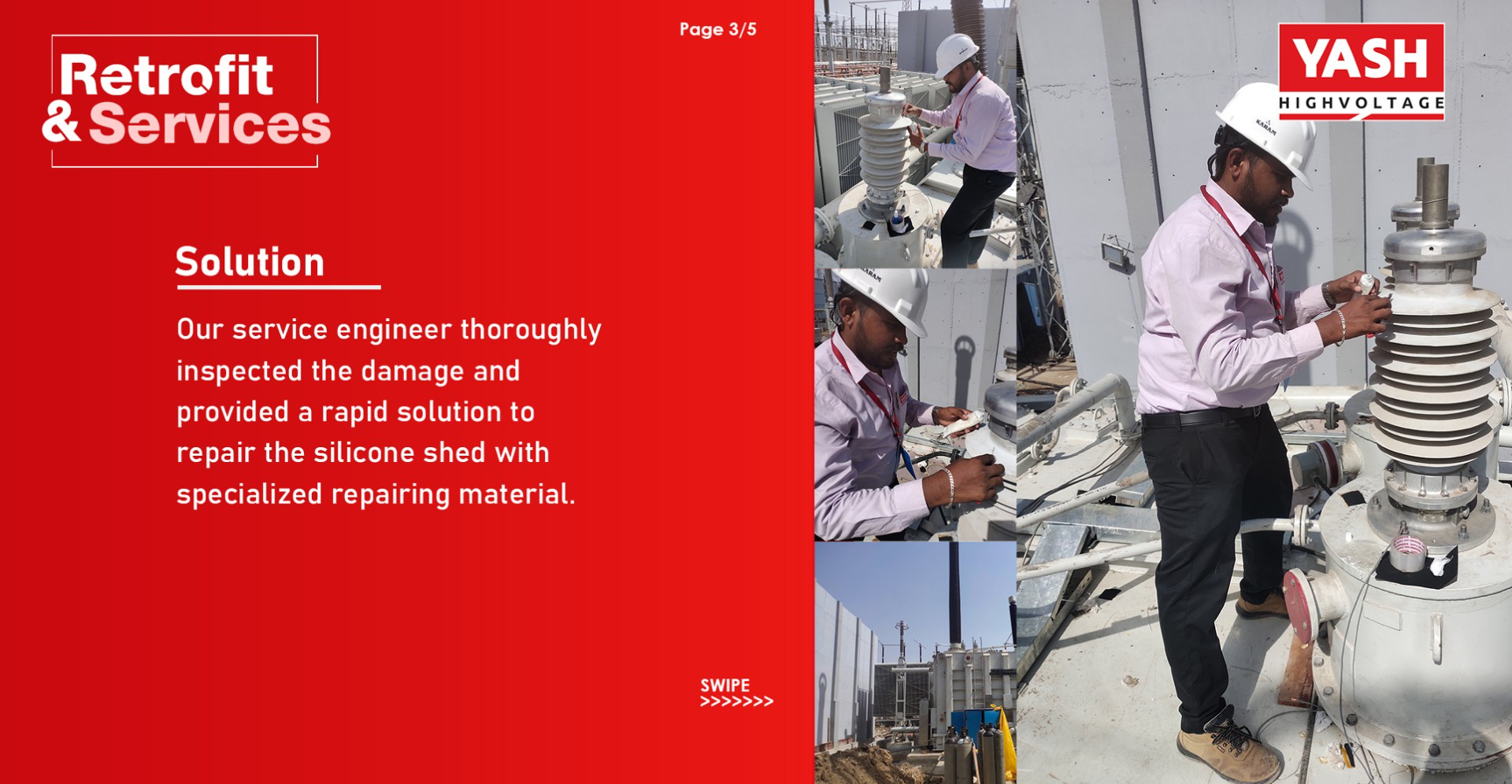

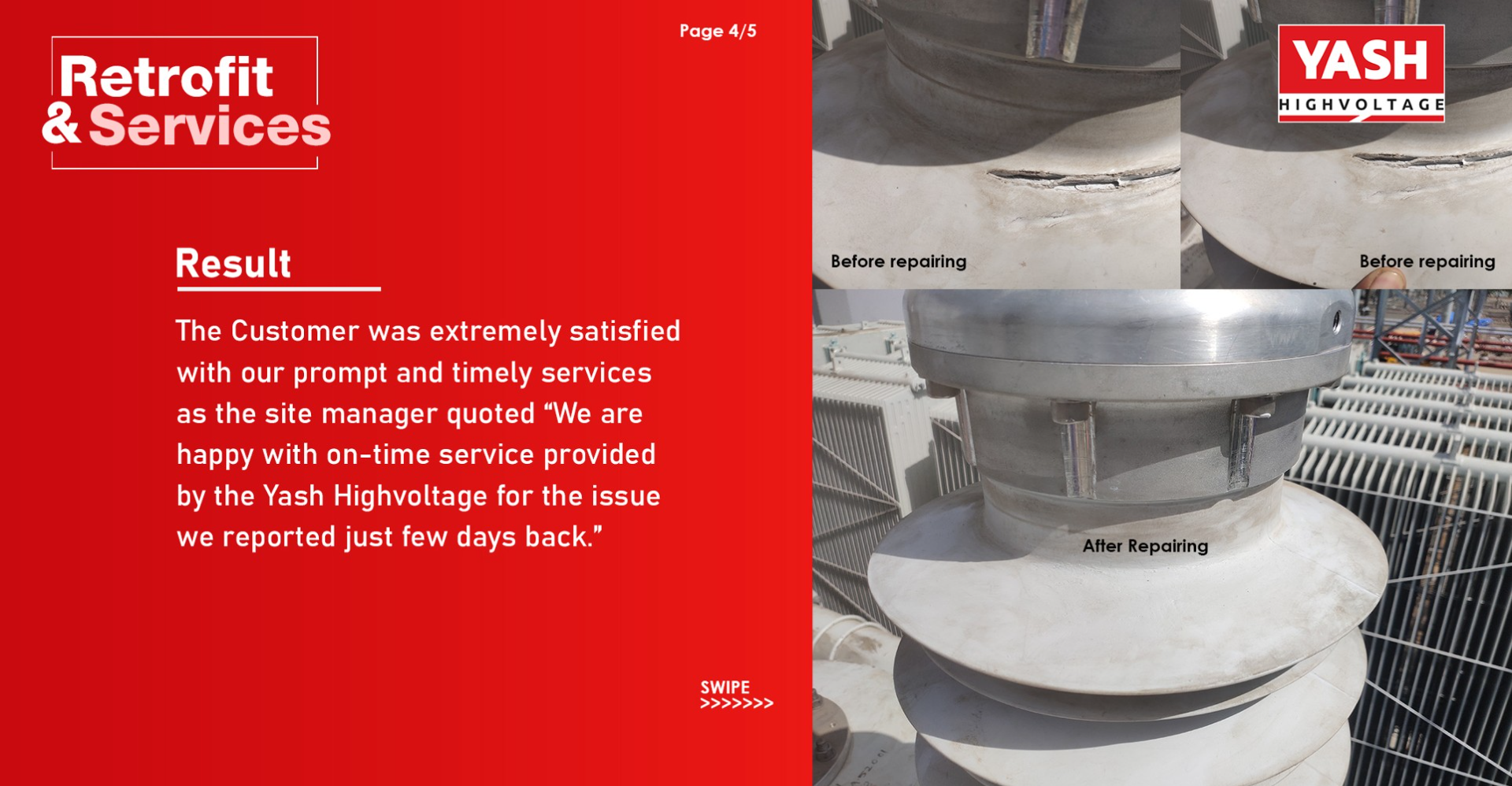

Recently, we were able to successfully repair a 500MVA transformer on site by fixing silicone shed damage on a RIP bushing. This type of damage can be costly if left unaddressed, as it can lead to substantial damage to the transformer and surrounding equipment. By providing rapid response and interchangeable solutions, we are able to meet the needs of our clients and maintain the functionality of their equipment.

If you have any inquiries about retrofit or repair services for transformer bushings, please don't hesitate to contact us at services@yashhv.com or sales@yashhv.com, or call us directly at +91 90990 86467.

A step toward a safe, sustainable, and efficient Power grid for the nation.

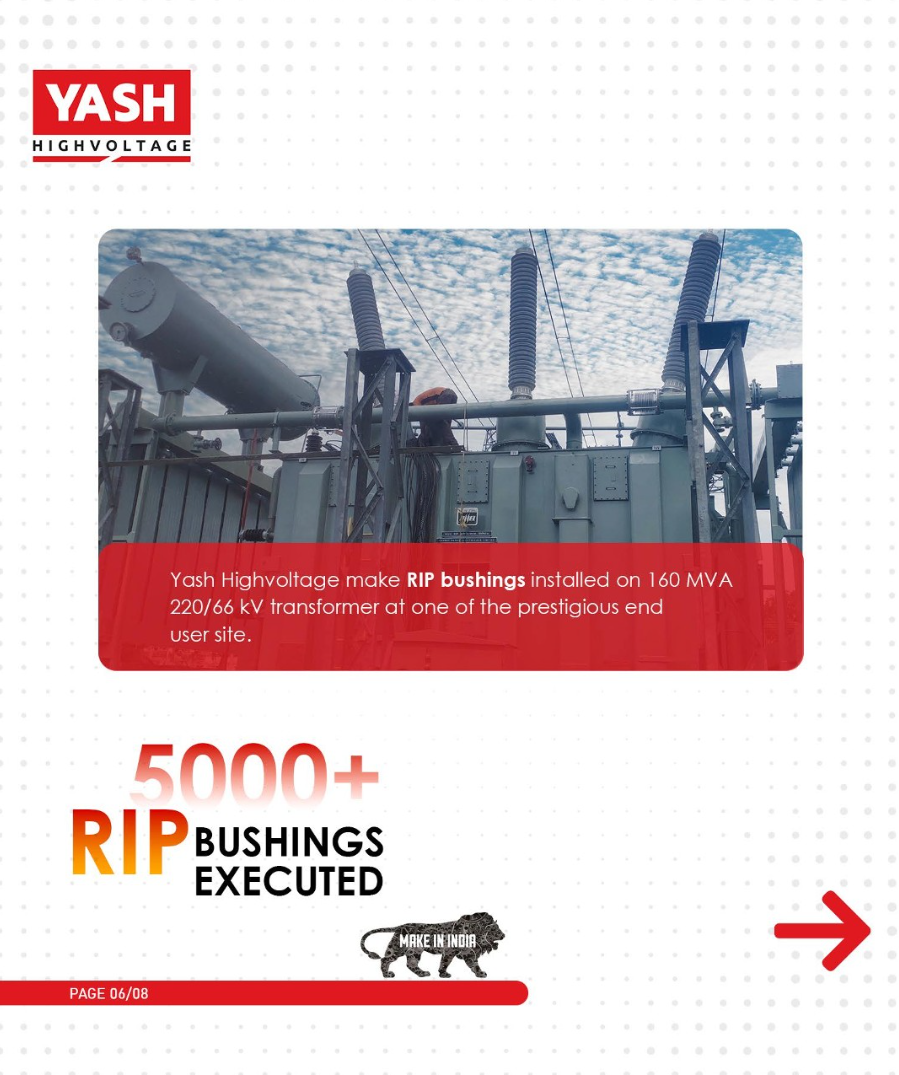

Recently, Yash Highvoltage completed a bulk order of 145 kV 3150 A 300 CT Resin Impregnated Paper (RIP) Bushings for a transmission utility in Northern India. These non-standard, special oil-air bushings are designed for use in transformers with very high short circuit loads and are part of our ongoing efforts to create a safer, more sustainable, and efficient power grid for our nation.

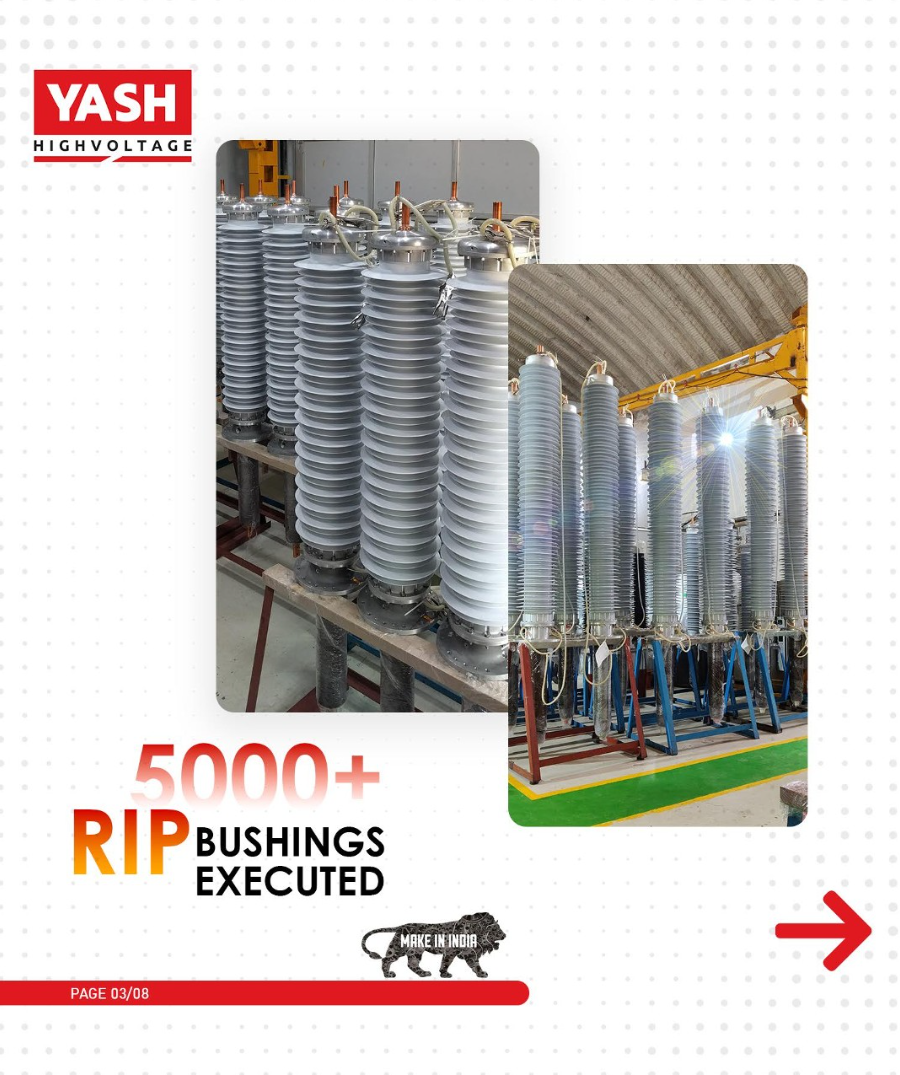

As a company, we were the first in India to localize the technology for RIP bushings under a technology collaboration with Moser Glaser of Switzerland. To date, we have manufactured and delivered more than 5,000 RIP/RIS bushings to various utilities through discerning transformer OEMs in the country.

Based in Vadodara, India, we are dedicated to providing top-quality transformer bushings solutions to our clients. If you have any questions or inquiries, please don't hesitate to contact us at sales@yashhv.com or sales.int@yashhv.com.

A Productive and Energizing Performance Planning Workshop at Yash Highvoltage Ltd. It was a productive, energizing, and rejuvenating day for everyone at Yash Highvoltage Ltd. as we had organized a performance planning workshop to plan, evaluate, and envision the performance deliverables for the coming years.

The workshop was not just limited to serious discussions, but it was also infused with jovial brainstorming exercises and eloquent activities. We are grateful to Bibha Jha Mishra, Zil Pandya, and Sudhir Kulkarni Sir from Naman Integrated Management Services Pvt. Ltd. for making the entire workshop vivacious. The workshop concluded with a few light moments, healthy discussions, and much-needed motivation from the dignitaries, including our Managing Director, KEYUR SHAH, and our General Manager of Business Operations, Nirav Patel.

>Watch the Full Video on our Youtube Channel<

Watch the little sneak peek from the Performance Planning Workshop'22!

Economy driving heavy industries like Sugar, Steel, Cement, and many others that have continuous batches of production require a continuous power supply.

Transformer bushings being a critical and major component in the power supply chain, their failure lead to disruptions/outages and heavy production losses.

In one such incident, one of India’s largest auto-grade steel manufacturer having roots in Eastern Region encountered a crisis of an emergency breakdown in the existing LV high current bushings on their Generator step-up transformers.

Yash Highvoltage Ltd. being an experienced and renowned player in providing out-and-out transformer bushing solutions, including repairing, and retrofitting with an interchangeable solution to existing bushings of any reputed international make; helped them by manufacturing and supplying a ditto interchangeable High current Copper condenser bushing of 24kV 12,500 Amperes

The 24kV 12,500A LV HC bushings match all the peculiar specifications of their existing old imported make bushings with exact dimensions in terms of mounting, BCT, Oil end length, Creepage, and Termination. The set of bushings is now successfully operational at the steel plant, having given new life to the transformer.

Recently, we had the opportunity to export a bulk consignment of 36kV 800A 0 BCT Low voltage OIP bushings to one of the leading manufacturers of power transmission and distribution equipment in the Middle East. These bushings were manufactured with the utmost precision and in accordance with the highest quality standards.

At Yash, we are committed to the motto of "Make in India – Made for the World," and we are proud to be growing as a preferred solution provider for transformer bushings, with clientele in over 45+ countries. Our premium range of bushings are manufactured in Vadodara, India, and we welcome inquiries from global transformer manufacturers and power developers for supply to the USA, LATAM, ASEAN, Canadian, European, African, Middle Eastern, and other markets.

For more information on our products and services, please don't hesitate to reach out to us at sales.int@yashhv.com or visit our website at www.yashhv.com. We look forward to the opportunity to work with you and help you meet your power transmission and distribution needs.

Growth is a vital aspect of any successful business, and one of the key pillars of growth is continuous and consistent learning. In order to stay competitive and adapt to changing market conditions, it is essential for businesses to continually educate and train their employees.

This is why we recently organized two days of training on internal auditing for Quality Management systems based on ISO 9001:2015 (aligned with ISO 19011:2018) for our employees. The training was designed to help our team learn how to effectively communicate and collaborate with both internal and external stakeholders, covering a range of key topics such as risk analysis, the Plan-Do-Act-Check (PDCA) method, guidelines for auditing management systems, and strategies for addressing the pain points of internal departments.

Overall, the training sessions were a great success, with positive feedback from our employees. Nitin Kulkarni, Divyanshu Saxena, Darshan Patel, Haresh Parekh, Hardik Kandoi, Abhishek Gupta, Dipen Patel, AJAY RANGANATH and Bharat Chauhan were all in attendance and actively participated in the training. It is through initiatives like these that we are able to foster a culture of continuous learning and growth within our organization.

Over the last 20 years, Yash High Voltage has become synonymous with innovation, and quality and has proven its reliability in the field of high voltage infrastructure by delivering world-class bushing solutions. In our mission to power ahead, we are continuously adding experienced and thoughtful leadership.

We are proud to welcome Mr. Anindya Basu as a Management Advisor for Business Excellence.

Mr. Basu has a successful track record in Managing Business for more than 18 years with several manufacturing units and 34 years of experience in the Electrical Power Transmission and Distribution Sector. He has the extensive industry experience and has worked with CG Power & Industrial Solutions Ltd. (Crompton Greaves Ltd.) as Business Head - Transformers, EMCO Ltd. Industrial Transformer Plant, Birla NGK Insulators Pvt. Ltd. (Jaya Shree Insulators) and Crompton Greaves Ltd., Nasik.

He has successfully turned around the Large Power Transformer Plant in Winnipeg, Canada, having an annual turnover of 70 million USD.

Mr. Anindya Basu has received awards and accolades for his remarkable work, to list a few, the Power Transformer Plant, Bhopal, under his Leadership, was adjudged as the Best Manufacturing Plant in entire Crompton Greaves Ltd., including overseas facilities, received “Manufacturing Excellence” award by Frost & Sullivan and personally received “Recognize” award at “CG Awards for Excellence” for Business Excellence. He has also been nominated for the Aditya Birla Group Chairman’s Award for individual excellence towards “Exceptional Contribution” and was adjudged as the “Best Manager” by the NGK, Japan Management Team for his excellent performance.

Mr. Basu is a Post Graduate Electrical Engineer (High Voltage) from IISc, Bangalore, and has management qualifications from IMD, Switzerland, and IIM, Bangalore.

His association with us will bring decades of industry experience & sharp business insights to the group. We are elated to welcome Mr. Anindya Basu on board and look forward to a bright future together.

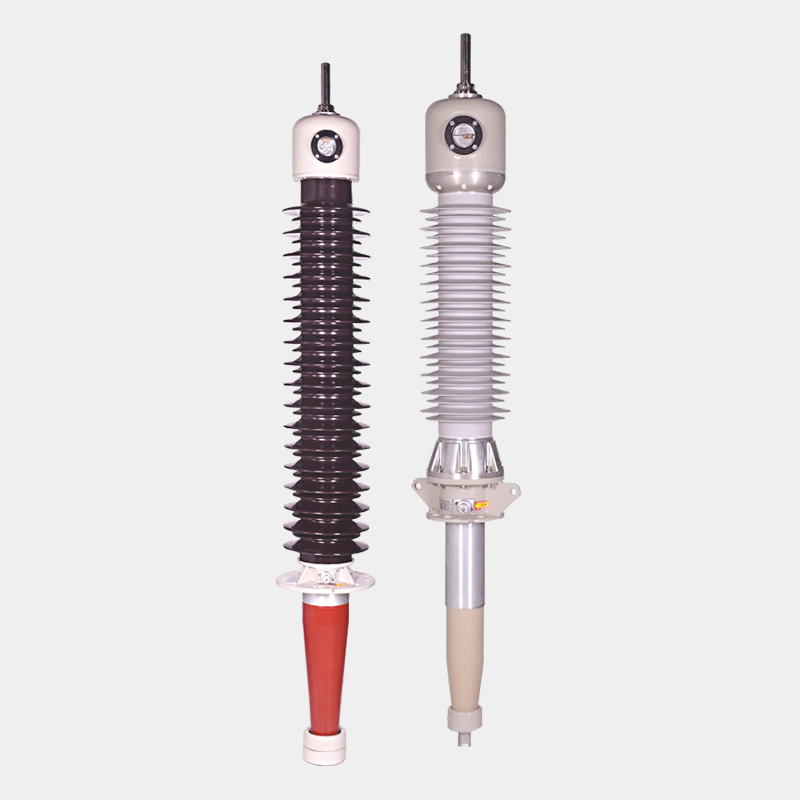

Resin Impregnated Paper (RIP) dry type bushings are the game changer for Power transformer and grid safety and reliability, and we at YASH take immense pride in being the First Indian manufacturer to have localized production of these futuristic products in India since 2016, under collaboration with Switzerland based Moser Glaser MGC – the pioneers in the field of solid insulation since the 1960s.

From the very first localized RIP bushings rated 52kV 6600A 300BCT executed by Yash for prestigious STATCOM projects of POWERGRID-India in 2016, today we have come a long way with a sizeable 5000+ Nos. RIP bushings executed from the state-of-the-art factory in Gujarat-India, covering a huge range from 24kV up to 245kV RIP bushings for National and State utilities.

With more than 20 RIP bushing models successfully type tested in India as per IEC 60137, and immense operational experience established by thousands of bushings in successful operation in the Indian Grid for over 3 years, YASH has emerged as a preferred name for bulk supplies of these innovative solutions in the country, having well productionized a varied range of voltages and currents as well as a seasoned execution and support team.

Mr. Keyur Shah (M.D, Yash Highvoltage) quoted, “It feels good to be recognized as one of the leading bushing manufacturing companies especially when big MNCs from the west are your major competitors. We have surely set a benchmark by executing 5000+ RIP/RIS bushings, but it is just the beginning. We will constantly strive to provide only the best in transformer bushing solutions to the power & energy industry.”

The complete range from 24kV to 245kV is available in the RIP as well as RIS (Resin Impregnated Synthetic) which is the latest in dry bushings technology from YASH-India, whereas RIP/RIS bushings >245kV up to 550kV are available from MGC Moser Glaser – Switzerland.

Yash Highvoltage and M/s. MGC Moser Glaser actively made its

presence felt at the renowned Coil Winding & Electrical Manufacturing Exhibition

– CWIEME 2022 held at MESSE Berlin between 10th – 12th May

2022.

The show was a super success as we received an immense response and a good number of walk-ins all three days of the exhibition.

Our booth was visited by erudite customers and prospects from major Transformer OEMs, Utilities, EPC Contractors, and Consultants from Berlin and nearby regions.

Mr. Nirav Patel (GM Business Operations, Yash Highvoltage Ltd.) quoted, “We always look forward to exhibit at CWIEME as it is visited by many intuitive visitors from Power & Energy industry. The three-day exhibition was a huge success for us this year as well, and it feels good to catch up with our customers after such a long break!”

We all from Yash & Moser Glaser team want to thank each & every patron for taking out their time and marking their presence at our booth.

We shall continue to provide the indigenously developed world-class Transformer Bushings and their smart solutions & rapid service to Power & Energy industry.

In an effort to meet the increasing global demand for power and energy, Yash Highvoltage has expanded its infrastructure with the addition of a state-of-the-art Extra High-voltage Test Laboratory. The construction of this lab, which took place over the course of 12 months despite various challenges posed by the COVID-19 pandemic, is a source of pride for the Yash team.

Watch the beautiful time-lapse video showcasing the journey from the foundation stone till the magnificent laboratory coming to life.

> Watch the Full Video on our Youtube Channel <

Featuring ultra-modern testing equipment from leading brands, this 550 kV EHV Test lab is capable of performing all routine tests as per IEC 60137:2017 standards and some special tests. Its addition to our facilities allows us to accommodate large volumes of HV and EHV condenser bushings to meet the needs of our global customers. With a total of two in-house HV test facilities now available, Yash Highvoltage is well-equipped to handle the growing demand for transformer bushings and deliver faster lead times.

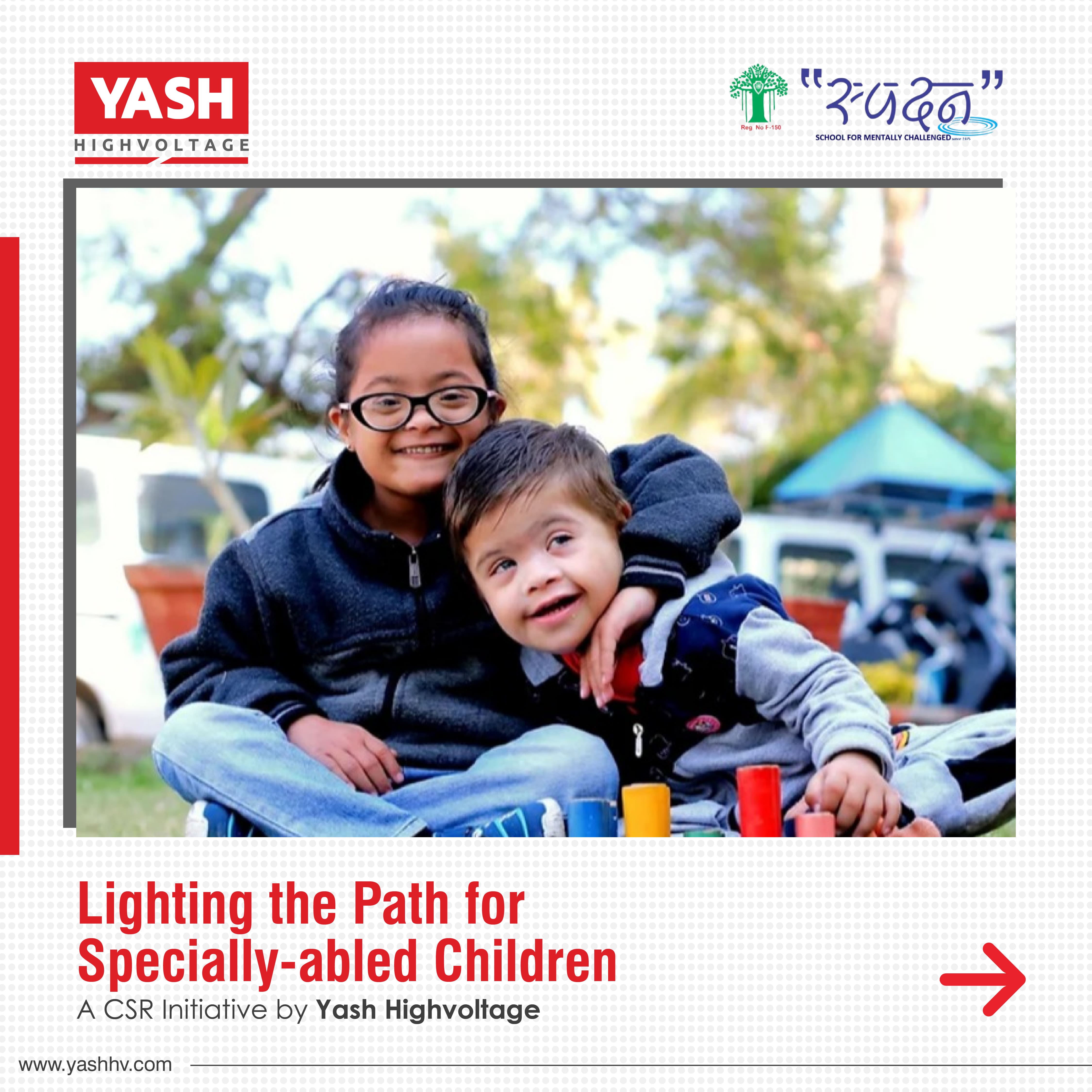

Yash Highvoltage illuminates possibilities: Supporting Spandan School for Differently Abled Children

At Yash Highvoltage, we believe in empowering dreams, potential, and future. Lighting up communities isn't enough, we strive to illuminate paths for everyone to shine. That's why we are proud to support the impactful work of Spandan School for Differently Abled Children, a beacon of empowerment for young minds with unique abilities.

Spandan's vision resonates deeply with us - a vision where every individual, regardless of limitations, has the right to shine. Their state-of-the-art development school provides a nurturing environment where children with special needs can develop self-respect, independence, and crucial life skills.

For Mr. Keyur Shah, Managing Director Yash Highvoltage, the impact of his leadership extends beyond business success. Investing in Spandan allows him to personally equalize opportunity and empower young minds with special needs, aligning with our company's core values of social responsibility.

Our recent contribution to Spandan School wasn't just about financial support, it was about investing in the future, in the possibilities waiting to be unlocked. By supporting their essential programs and services, we help pave the way for these children to:

Receive specialized education: Spandan's experienced and dedicated educators cater to individual needs, fostering academic growth and personal development.

Develop life skills: From daily routines to vocational training, Spandan equips children with the practical skills they need to navigate the world with confidence.

Nurture self-esteem and independence: Spandan celebrates individuality and provides a safe space for children to discover their strengths and embrace their unique potential.

We are proud to be associated with Spandan School in their mission to illuminate the path for these exceptional children. We believe that every spark of potential deserves the chance to shine, and by working together, we can create a brighter, more inclusive future for all.

In a heartwarming initiative, Yash Highvoltage has donated three table-top pulse oximeters to the pediatric ward of SSG (Sir Sayajirao General Hospital) through the Rotary Club of Baroda Cosmopolitan (RCBC) foundation. These medical devices will play a crucial role in monitoring the oxygen levels of infants without the need for invasive blood tests. Yash Highvoltage's generous donation to SSG Hospital will contribute to improved healthcare for countless children seeking treatment in the pediatric ward. These advanced pulse oximeters will enable faster diagnosis, better-informed treatment decisions, and ultimately, improved health outcomes for children. "Seeing a smile on a child's face is the greatest reward," says Mr. Keyur Shah, Managing Director of Yash Highvoltage. Yash Highvoltage hopes to contribute to a brighter future for the children. This effort sends a message of hope and support to the families of children receiving care at SSG Hospital. It demonstrates that even small but impactful actions can make a significant difference in the lives of others. By choosing to invest in the health and well-being of children, Yash Highvoltage is shaping a brighter future for the community.

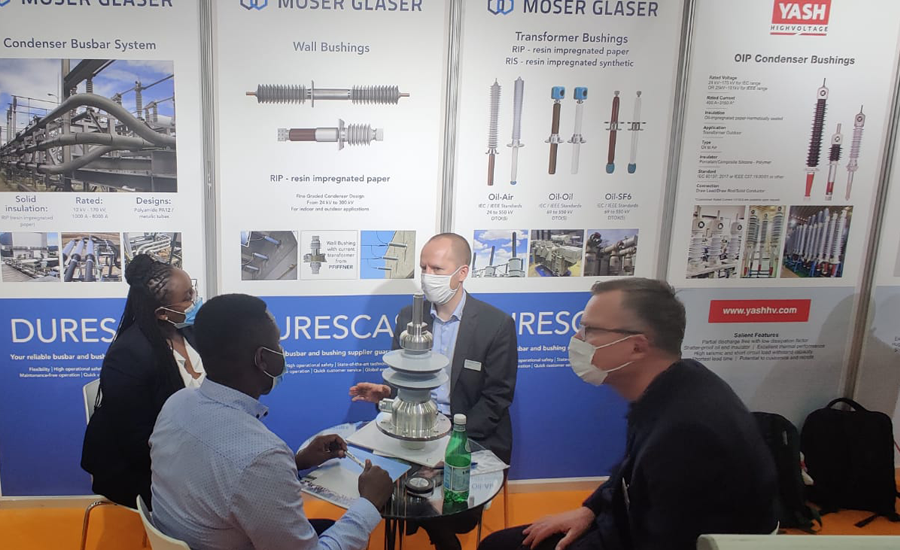

In our continual efforts to share knowledge and educate our patrons and users of our products with the latest technological advancements in the Electrical Industry, YASH Highvoltage Ltd along with our partner M/s. MGC Moser Glaser arranged a series of seminars across India on the latest Solid Insulation technology for transmission of energy in medium and high voltage equipment, such as transformer - switchgear connections or generator – generator breaker – transformer connections.

During this event we were happy to share possibilities of various applications for RIP busbar systems by MGC and localized RIP bushings including retrofit solutions to a distinguished audience comprising of noteworthy End Users, Consultants and Contractors of the country.

Solid insulated busbars provide a safe, reliable, compact, maintenance free and a fully electrically shielded solution against a cable connection or conventional air-insulated busbars. The individually insulated busbars are simple and quick to assemble and guarantee a long and maintenance-free operation, since each component passes through a routine test and therefore is delivered without any partial discharge.

YASH’s inaugural stall at MEE along with our partner M/s. MGC Moser Glaser was greeted with great response from discerning customers including some of the major Transformer OEMs, Utilities, EPC Contractors and Consultants in the Middle East at the recently convened Middle East Energy Exhibition at Dubai between 7th – 9th March.

Our booth was visited by many existing as well as new customers and potential partners and we thank all our patrons for taking out the time tio visit us. It was a surreal experience to return to physical exhibitions after such a long break due to COVID and to meet up with friends, customers and representatives after such a long time.

With

the goal of “Made In INDIA for the WORLD” YASH continue to reach out and serve

the global customers with the indigenously developed world class Transformer

Bushings and we invite Inquiries from our global customers.

We are excited to announce that a large shipment of 24 kV 1250 A 100 CT RIP Bushings is currently in the final stages of production for a prominent customer in western India. These bushings are known for their exceptional performance and are part of our line of DRY TYPE Resin Impregnated Paper (RIP) /Resin Impregnated Synthetic (RIS) Condenser Bushings.

Our RIP and RIS bushings are oil-free transformer bushings that feature insulation built directly on the conductor. The insulation for RIP bushings is made up of high-quality crepe paper wound on the conductor, while RIS bushings use a special grade synthetic film. Both types of bushings offer reliable insulation and performance.

If you have any inquiries about these bushings or any of our other products, please don't hesitate to reach out to us at sales@yashhv.com or sales.mum@yashhv.com. We would be happy to assist you.

A full set of YASH Highvoltage Ltd. make RIP bushings from 220kV, 145kV, 72.5kV and 36kV for HV, LV, HV Neutral and LV Neutral installed and performing satisfactorily on a beautiful 100 MVA transformer of one of discerning OEM customers, at a prestigious EHV substation site in Western India.

The customer has commissioned the transformer since 1 year and was glad to provide a positive performance feedback on the YASH make RIP bushings upto 245 kV performing satisfactorily since 1 year of commissioning.

There are now several positive references of YASH make RIP bushings performing nation wide on commissioned transformers, many of which are operational for more than 3-4 years now.

With more than 4000 localised RIP bushings now under operation pan INDIA and also abroad on Indian transformers, our customers have now well accepted brand YASH for their needs on RIP/RIS bushings.

In 2022 we marked a major milestone by addition of a state-of-the-art EHV test lab capable of efficient throughput and swift handling and testing of large volumes upto 245 kV rated bushings. The addition of this lab now makes available a total of 2 in house test facilities enabling excellent lead times and cater bulk requirements for the rapidly growing demand for transformer bushings globally.

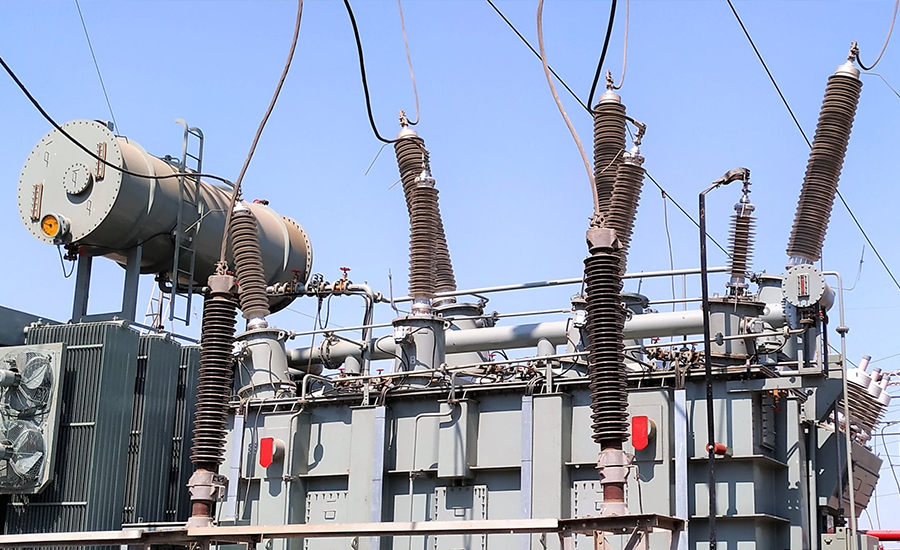

A transformer bushing acts as a critical exit and entry pathway to conduct power safely from/to High voltage Power lines in an out of a Power Transformer, while providing sealing to prevent contact of Transformer Oil with Air.

Bushing failures constitute the third largest cause of transformer failures globally and this is one of the key reasons why it takes a significant effort and the combination of a wide array of resources to establish as a trusted solution provider for these critical components.

With 20,000+ products successfully executed, YASH has now emerged as a niche and trusted player among a list of very few globally reputed transformer bushings manufacturing MNCs.

We thank all our patrons, suppliers, team members and stake holders for supporting us in achieving this milestone and look forward to creating many more like this in the coming years.

We are proud to announce the execution and supply of a prestigious export consignment of 170kV, 145kV and 72.5kV "OIP Capacitive bushings with Polymer/Silicone insulators" to a prestigious Transformer customer in "Italy" for end use with the prestigious "Italian Railways". YASH’s Sales and Engineering teams were extensively with the transformer customer during detailed engineering stage to arrive at an interchangeable solution to meet the customer’s stringent specifications including high altitude applications and could offer a design at par globally reputed European bushings suppliers.

The order was executed in a record time of 3 months despite being non-standard and special in nature and despite the challenges posed by COVID pandemic and the related delays.

Transformer bushings - "Made in India - Made for the World"

Knowledge sharing about critical accessories of Power transformers, such as Bushings thorough webinar organised by IEEMA (Indian Electrical & Electronics Manufacturer Association)

YASH could recently export a consignment of 123 kV 800A 0 BCT OIP bushing with special arrangement for retrofitting with the customer's specification as a replacement to existing bushings at site. The bushings are enroute now on a 15000 mile journey: to Final destination on the West coast of Latin America, for a renowned Power Transmission utility.

We at YASH specialise in offering custom engineered bushings solutions to meet the non-standard requirements of the end users be it in terms of the special termination arrangements, special mounting arrangements, non standard BCT space and oil end length requirements etc thereby providing a ONE STOP SOLUTION for TRANSFORMER BUSHINGS.

Quality has been one of the key focus areas of YASH make 145 kV OIP Condenser Bushings. Time and again our products are put to the test in most critical conditions, whether it is in the test field or in extreme service conditions.

Our products have proven themselves several times in the most stringent of tests whether tested stand alone or with the transformer.

One such recent achievement was successful performance of YASH make 145 kV OIP bushings during short circuit testing of 160 MVA transformer of a reputed Indian Transformer OEM.

Heavy Industries such as Steel, Cement, others which rely on continuous bulk production round the clock have a critical need of continuous power supply. A transformer bushing being a critical component in the power supply chain can cause major disruption and heavy production losses during breakdowns.

A renowned Steel Industry having a major captive power plant in the eastern part of India experienced one such emergency breakdown of the existing LV high current bushings on their Generator step up transformers and approached YASH to offer an urgent retrofit solution to the existing imported make bushing.

Within record times YASH could design, develop, manufacture and supply a ditto interchangeable Copper condenser bushing of 36 kV 16000 Ampere which is now operational at the Steel plant.

YASH has been a pioneer in providing custom made and specially designed solutions across the Industry, be it the Transformer OEMs or directly to the end users such as Generating/Transmission Substations.

There are many products in service which are either near the end of their service life or have developed some deficiencies and require replacement, however the end users face challenges as the original supplier have either discontinued those designs or have all together exited the market.

We recently executed one such high current bushing order, the design of which has now been obsoleted by the original bushing manufacturer. The end user which is a Nuclear Power Generating Substation welcomed this ditto interchangeable 5500 A High Current bushing with customised connectors by YASH which gave an extended life to their old transformer by replacing the existing bushing.

In the true spirit of “Made In India For The World”, YASH High voltage is proud to announce another successful supply of a specialised 36 kV 16000 A high current bushing solution this time for a Combined Cycle gas turbine power plant around 9000 miles away.

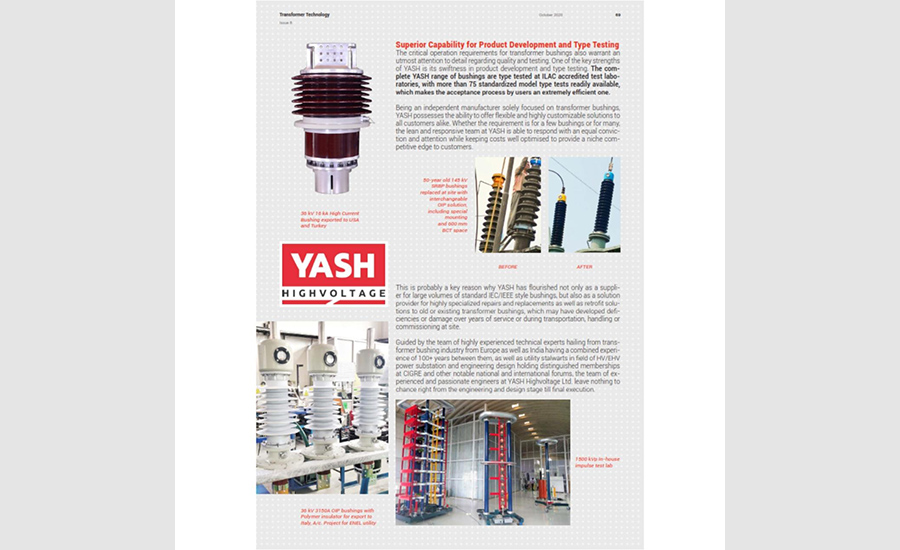

YASH, being an independent manufacturer solely focussing on transformer bushings, YASH possesses the ability to offer flexible and highly customizable solutions to all customers alike be it the Transformer OEMs or the end users and power developers. Whether the requirement is for a few bushings or for many, the lean and responsive team at YASH is able to cater them with an equal conviction and attention while keeping costs well optimised to provide a niche competitive edge to customers in Industry best lead times.

Yash is proud to announce availability of it's brand new OIP condenser bushing range as per IEEE - from 25kV upto 161 kV Voltages, in addition to the well established IEC product range from 24kV upto 170kV.

We are happy to add another supply reference of 69 kV 800A 534BCT OIP Condenser bushings as per IEEE C57.19.00/01 standard for a transformer customer in the AMERICAs.

Tribute to the inspirational Atmanirbhar Bharat initiative, with our premium range of bushings manufactured right here in India, we invite inquiries of global transformer manufacturers exporting to the USA/LATAM/Canadian/European/African/Middle Eastern/GCC/South East Asia and other markets where you require IEEE/IEC style OIP condenser bushings. These products are available in brown/grey porcelain or grey polymeric silicon hollow insulators, suited as per the customer requirement.

BEST SUPPLIER AWARD bestowed by the country’s Navratna PSU M/s. Bharat Heavy Electricals Ltd. (BHEL)

YASH is thankful to M/s. Bharat Heavy Electricals Ltd. (BHEL), a Navratna PSU’s for the honour and the prestigious award of BEST SUPPLIER in Category of “IMPORT SUBSTITUTION UNDER MAKE IN INDIA INITIATIVE” for localized development and supply of innovative Resin Impregnated Paper (RIP) transformer bushings under technology from Moser Glaser (MGC) – Switzerland.

We as YASH Highvoltage are humbled to have received this award and the trust of the country’s premier PSU and shall continue in pursuit of excellence going forward.

.png)

.jpg)

.png)